Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Aug 07 /2023

share to

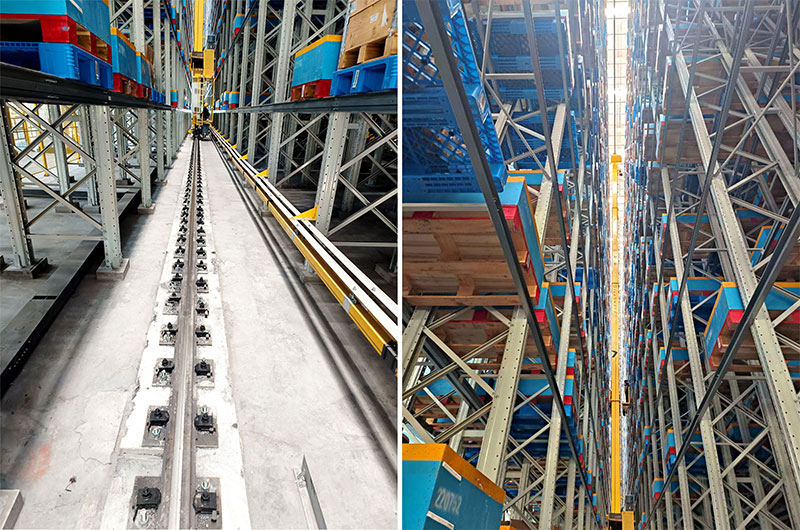

According to the official measurement of China Earthquake Networks Center, a 5.5 magnitude earthquake occurred at 2:33 on August 6 in Pingyuan County, Dezhou City, Shandong Province. The 45 meter super high stacker system of BlueSword Intelligent Super Logistics Center is only 29 kilometers away from the epicenter area in a straight line, and the vibration is very obvious. With the SPS safety warning and protection system of the stacker crane, we have withstood the test, quickly checked the system status after the earthquake, and quickly restored system operation!

On the morning of August 6th, the technical team of BlueSword stacker first conducted a visual inspection of the ultra-high stacker area, quickly investigating the appearance of the shelf structure, stacker structure, scattered pallet goods, and pallet displacement. With the comprehensive seismic structural design of the shelves, there were no visible abnormalities in the overall area. To ensure the absolute safety of the system, technical personnel continued to activate the SPS safety warning and protection system of the stacker crane and conduct further inspections of the equipment in the storage area.

Stacker System Quick Inspection Team

Stacker maintenance platform makes inspection work more convenient

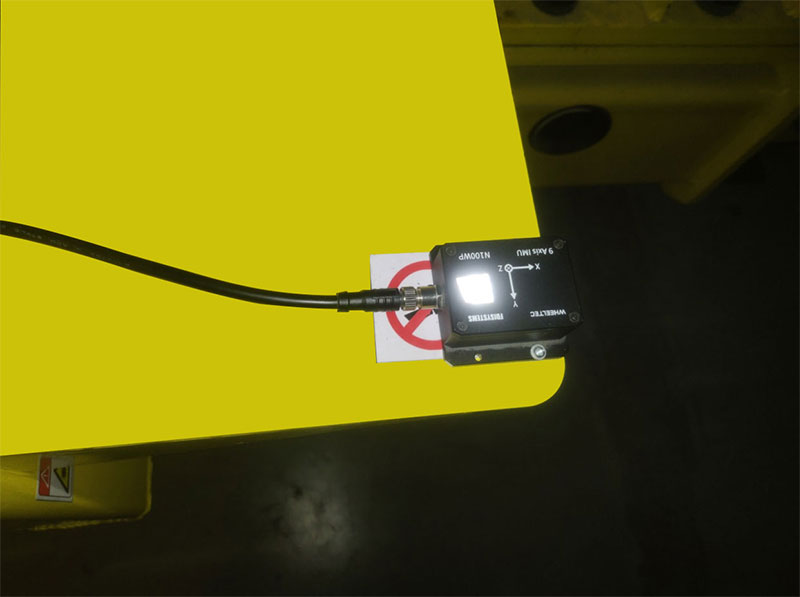

SPS gyroscope safety warning detection

By installing gyroscope sensors on the stacker crane, it is possible to quickly sense whether the stacker crane has abnormal tilting and swinging under static or dynamic conditions. By displaying the data of the static gyroscope of the stacker crane, it is possible to quickly determine the deviation changes of the main structures of the stacker crane, such as the column, upper crossbeam, and lower crossbeam; By displaying the data of the gyroscope during low-speed operation of the stacker crane, the health status of the supporting ground and sky rails can be quickly checked.

After comprehensive inspection data analysis, there were no abnormalities in the main body and supporting tracks of the ultra-high stacker crane after the earthquake.

Gyro Sensor

Conduct inspection on the ground orbit and sky orbit

ETI intelligent electronic tray detection

After a strong earthquake shaking, the main structures such as rack columns and beams may experience tilting deformation, seriously affecting the safety of goods and personnel. The traditional manual inspection method is inefficient and has inspection errors. ETI intelligent electronic pallet detection involves deploying various sensors on the electronic pallet and placing them on the forks of the stacker towards the cargo space. It can quickly detect various data such as the verticality and levelness of shelves in different areas.

The storage area of the ultra-high stacker crane system has a total of 3754 storage spaces. The technical team randomly inspected 187 storage spaces (5% sampling ratio), and the data showed that there were no abnormalities in the verticality and levelness of the storage shelves after the earthquake.

Space safety sensor detection

Strong vibrations can also lead to deviation and displacement of palletized goods on the shelves, and in severe cases, external exploration may occur, occupying the safe operating space of the stacker crane. The front end of the 45 meter ultra high stacker crane is equipped with a space safety detection sensor, which can achieve a full range of foreign object recognition from top to bottom of 45 meters.

After the earthquake occurred, technicians operated the stacker crane at low speed and level throughout the entire process to detect whether there were serious external intrusion of goods into the safe operating space.

After testing, it was found that the safe operating space of the stacker crane was normal after the earthquake, and there were no foreign objects obstructing it. There was also a small displacement of some pallets in the storage area (a total of 45 pallets were displaced, with a maximum displacement of 2.7 centimeters), which did not affect the normal operation of the equipment.

Scenario of maximum tray displacement after earthquake

Intelligent anti-collision system protection

Due to the impact of earthquakes, some pallets may experience some displacement due to strong vibrations, resulting in incorrect position of the pallet jack. If the stacker is not operated properly, it will push the goods out of the shelves, causing a safety accident of falling. In response to abnormal situations such as tray deflection and displacement, and incorrect jack, the BlueSword intelligent stacker is equipped with two sets of solutions: contact and non-contact intelligent anti-collision, effectively preventing the safety hazards of forks pushing goods down.

The contact type intelligent anti-collision cargo device is equipped with contact points at the front end of the cargo fork. When the cargo fork comes into contact with a displacement pallet during the pickup process, it will report the contact signal within 30ms and execute a shutdown command. At the same time, the cargo fork will immediately stop running within 50mm to avoid pushing the cargo over, ensuring the dual safety of the equipment and cargo.

The non-contact 3D visual correction function intelligently identifies the displacement, angle, and fork hole damage of the pallet using 3D visual technology, and actively corrects and warns based on the recognition results. It discovers that the pallet does not meet the pickup requirements before the fork pickup action, and therefore does not perform the pickup action to ensure the safety of the pallet goods.

BlueSword Intelligent Product Concept

The core concept of BlueSword intelligent product research and development is to "create valuable innovation". Products should create value for customers, enable them to truly use and benefit, and this is the only valuable product. At the same time, the value of a product lies not only in efficiency, aesthetics, and intelligence, but also in overall safety, adaptability in destructive scenarios, and the self-healing ability to quickly detect and recover from unexpected situations. At critical moments, we cannot drop the chain, can withstand tests, and consider our customers more. The BlueSword Intelligent R&D team always takes this as the goal, creating more comprehensive products, and truly serving users and friends in various industries.

Fill out your information, BlueSword will provide you professional service!