Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

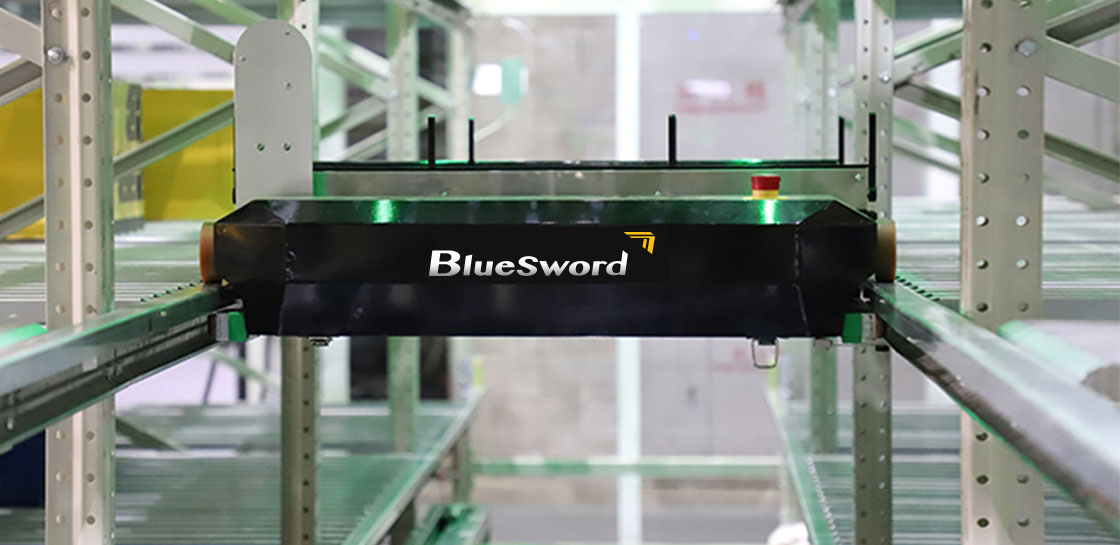

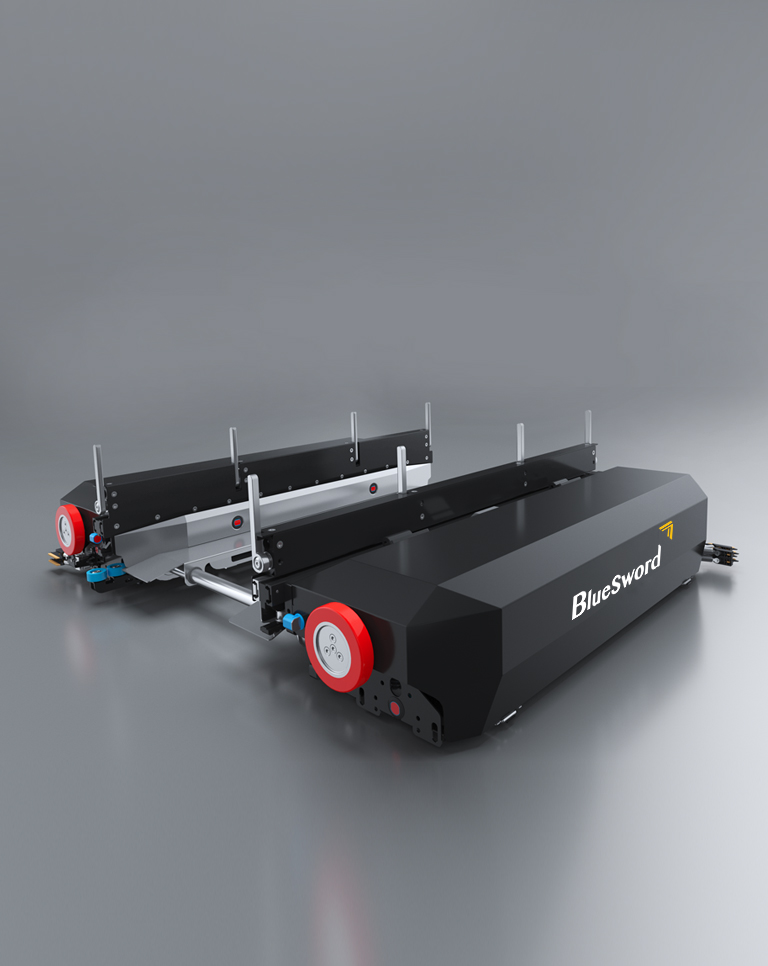

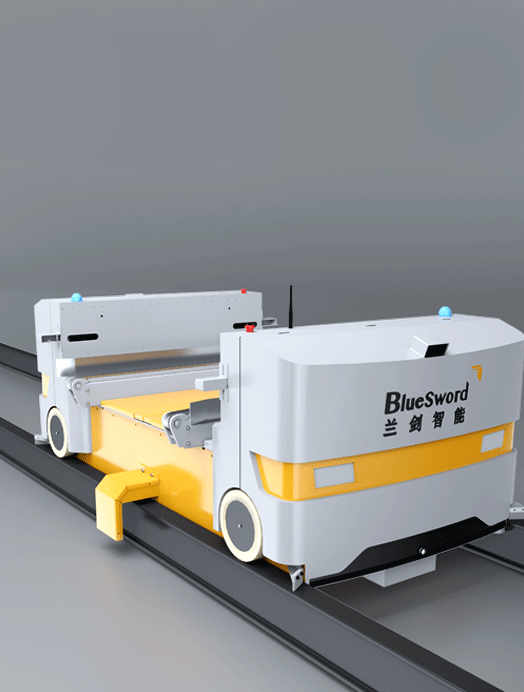

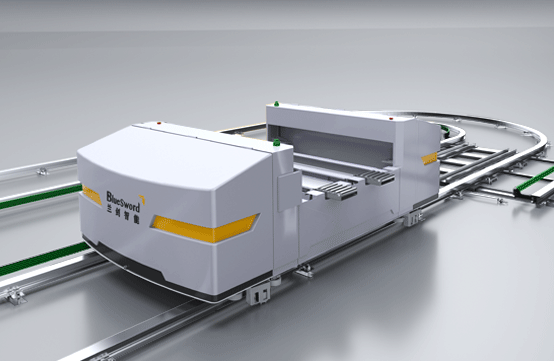

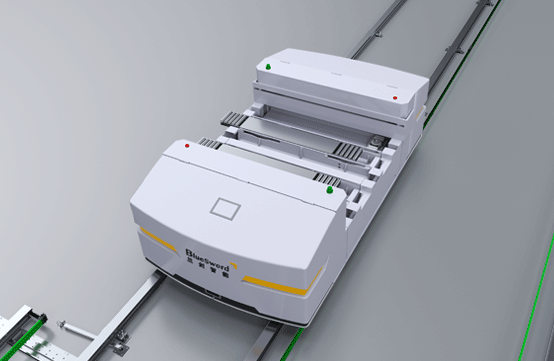

BlueSword is one of the earliest domestic logistics equipment enterprises in the research and development of shuttle robots, standing at a high starting point, to achieve rapid iterative and leapfrog development. Our products occupy a dominant position in the world in terms of amount of use and business breadth.

All-round adaptation

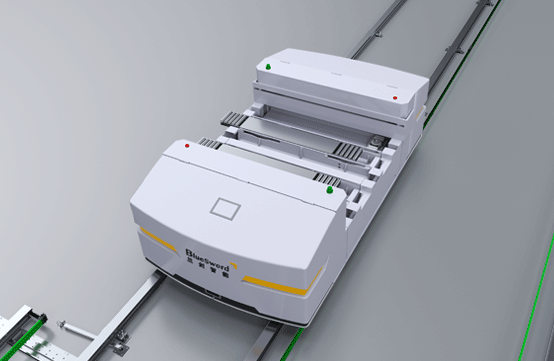

All-round self-correction

All-round test

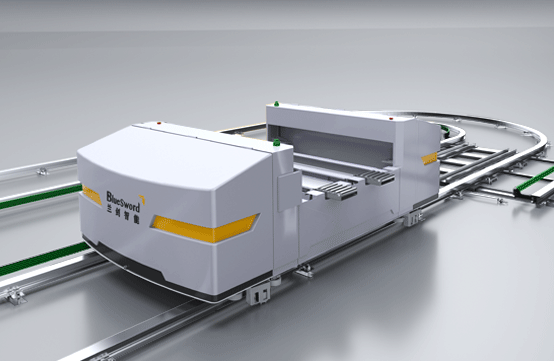

High productivity

Advanced design

Ultra low noise

We have comprehensive product specification, can deal with a variety of sizes and temperature, high efficiency requirements, layer change buffer and other solutions.

Using our case displacement detection technology, it can self-detect the unexpected offset of the front and back, left and right, and rotating case, and automatically correct the deflections to achieve zero deflection, zero failure.

With a complete set of shuttle test platform, it can test 24 shuttles at the same time in a single day.

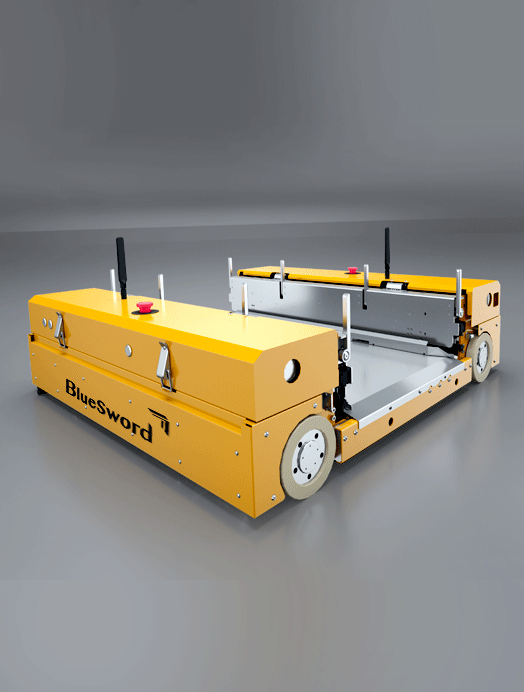

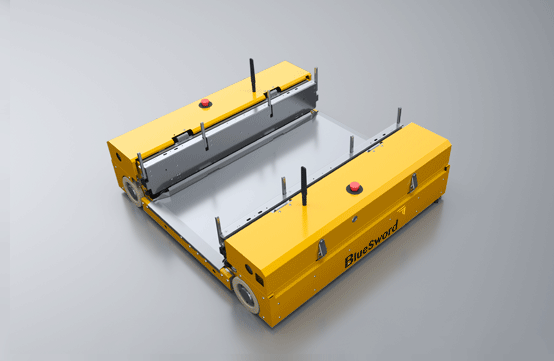

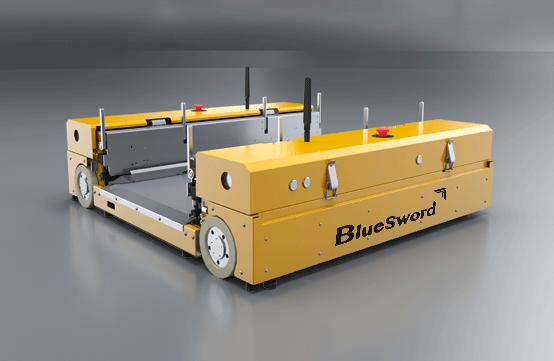

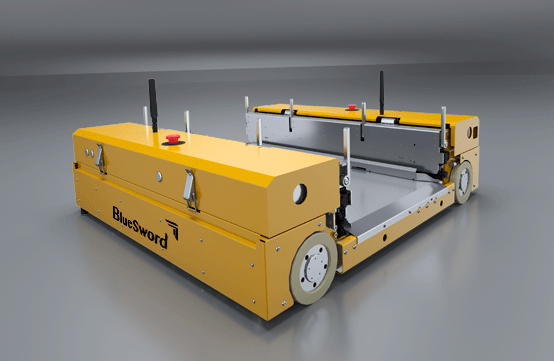

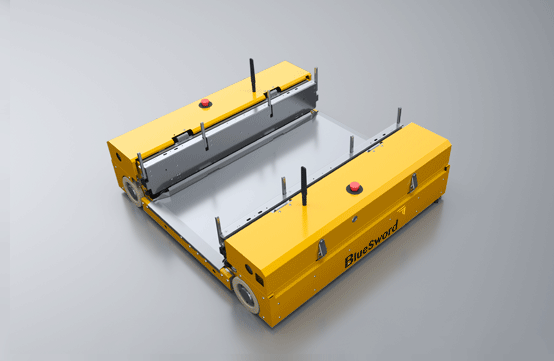

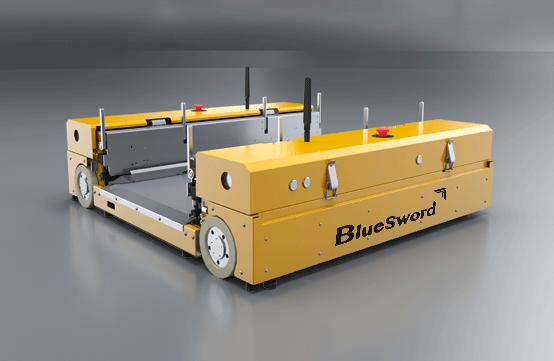

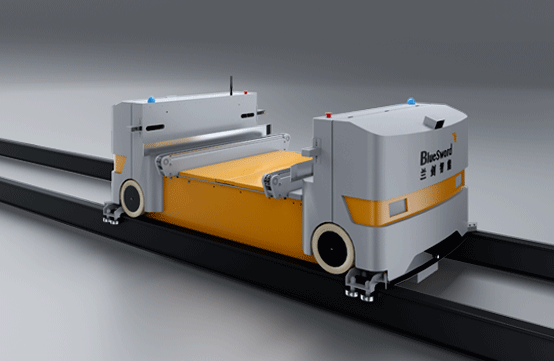

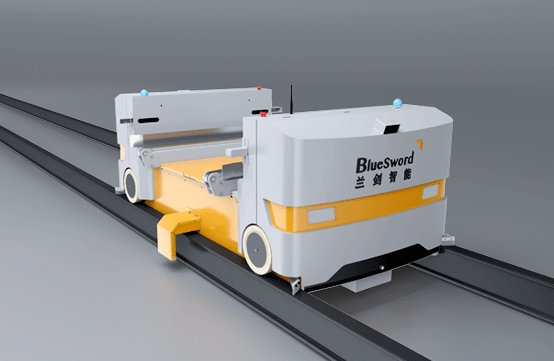

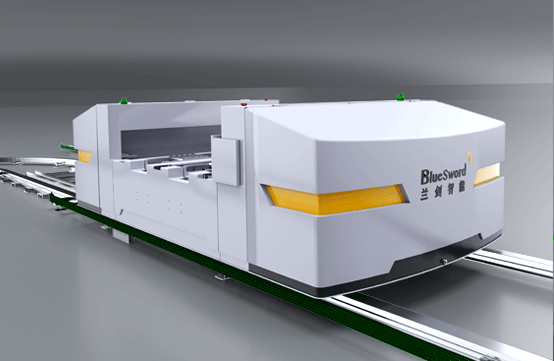

Mechanical and electrical modular design concept is fully modular design, modular installation, sub-system operation, equipment productivity improved by 4 times, the system operation efficiency improved by 2 times.

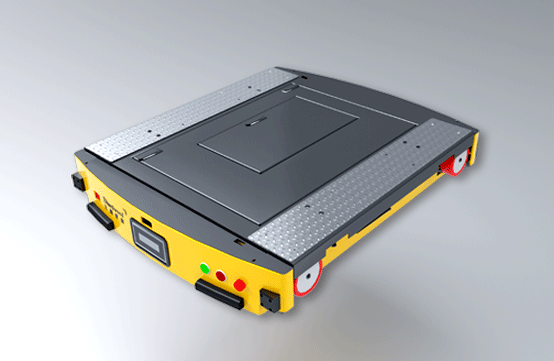

A large number of use supercapacitor charging technology, S-curve acceleration and deceleration technology, micro servo technology, chainless power supply technology and other independent innovation technology.

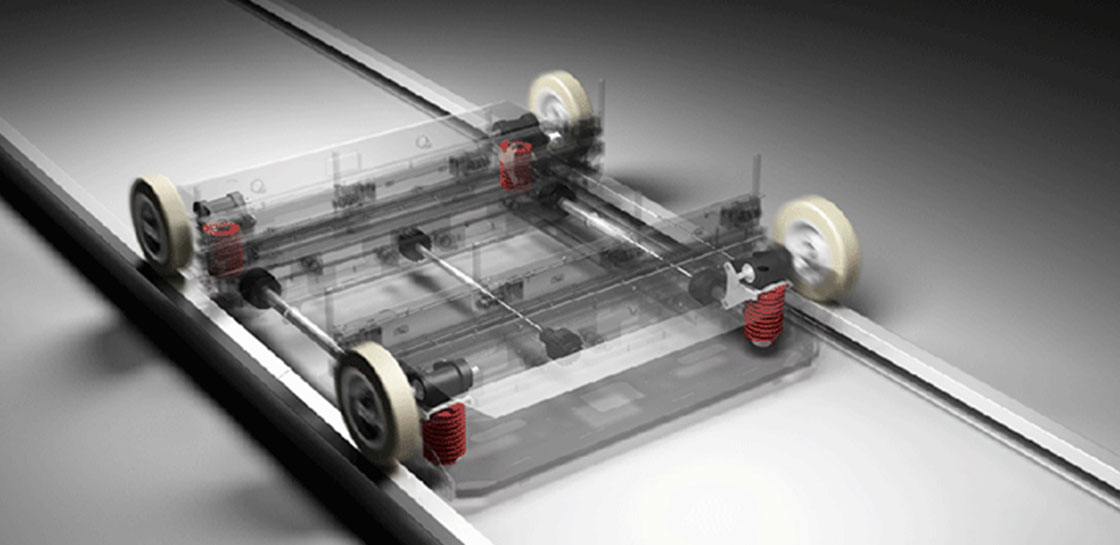

The shuttle has the technology for a four-wheel independent suspension, causing less vibration and less noise.

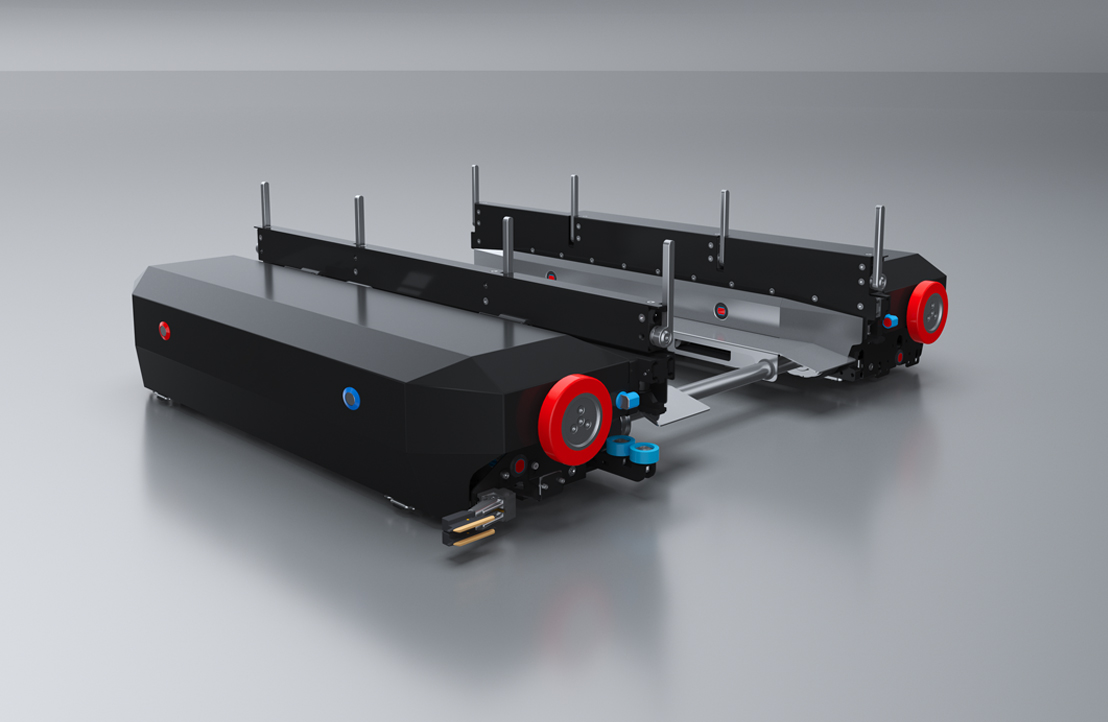

Four directions travelling, cross-aisle operation, give the project layout great flexibility and diversity.

Straight travel speed 4 m/s.

Straight travel acceleration 2 m/s².

Lateral travel speed 2 m/s.

Lateral travel acceleration 1 m/s².

Fork extend speed 0.9 m/s.

Fork extend acceleration 1 m/s².

Straight travel positioning accuracy ±1 mm.

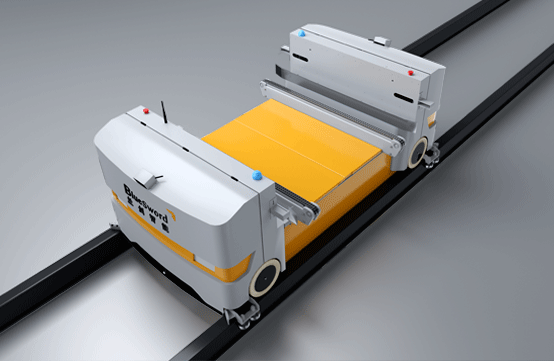

Automatic complete any depth, any location of pickup, drop-off, handling and other tasks.

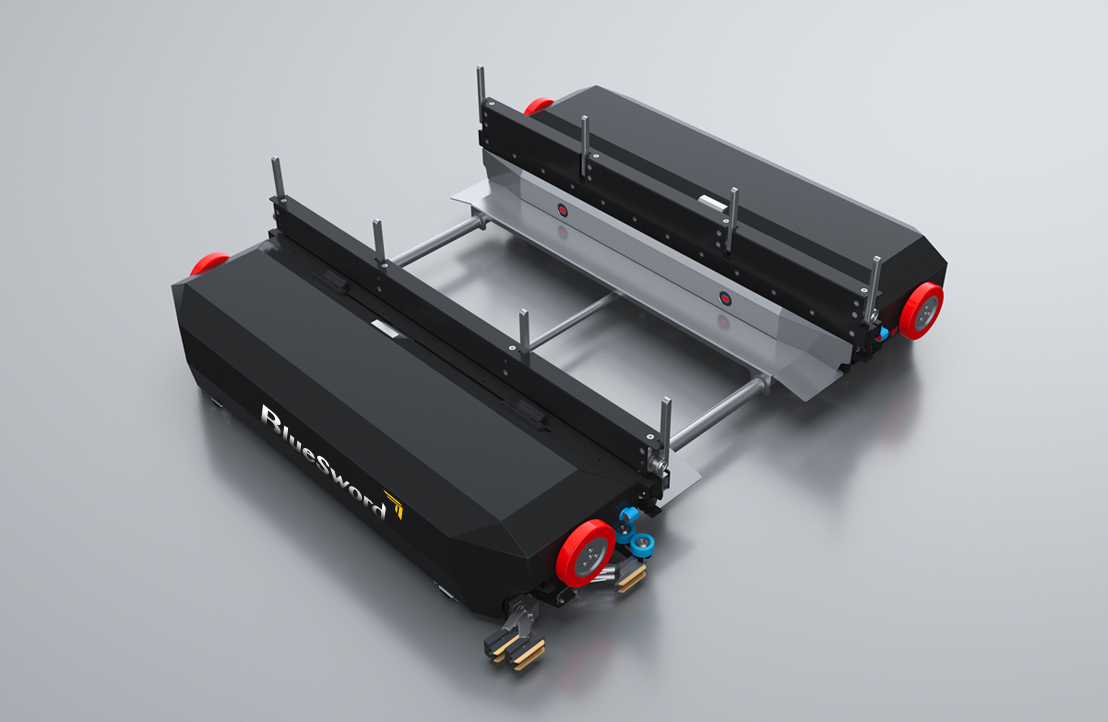

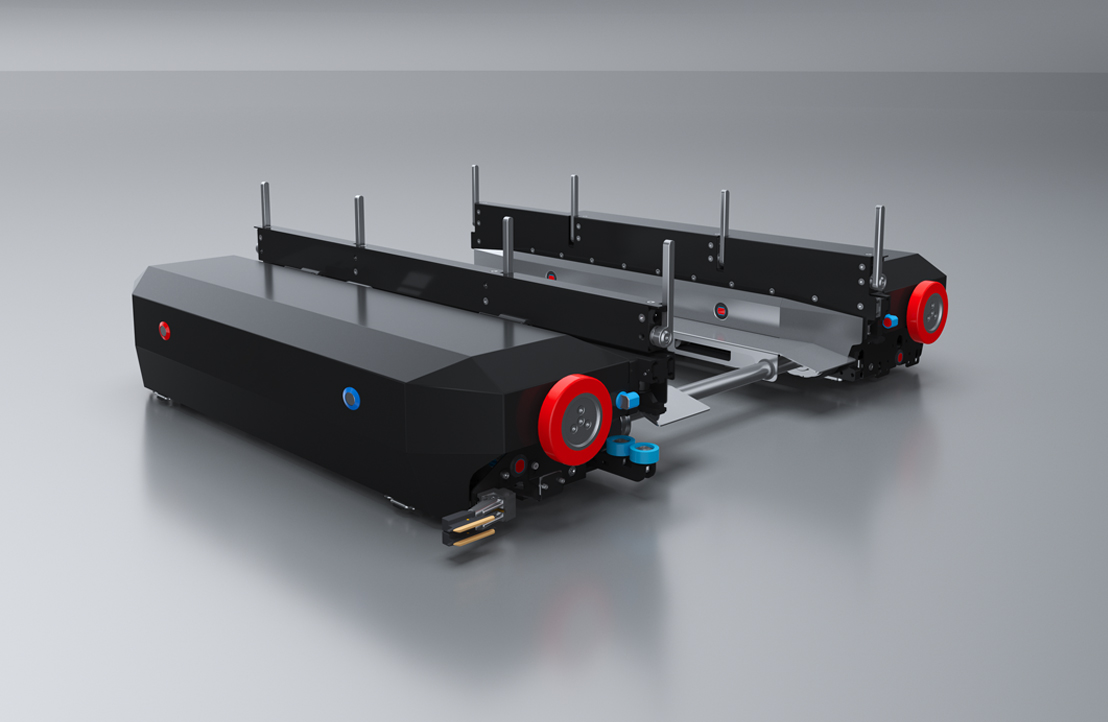

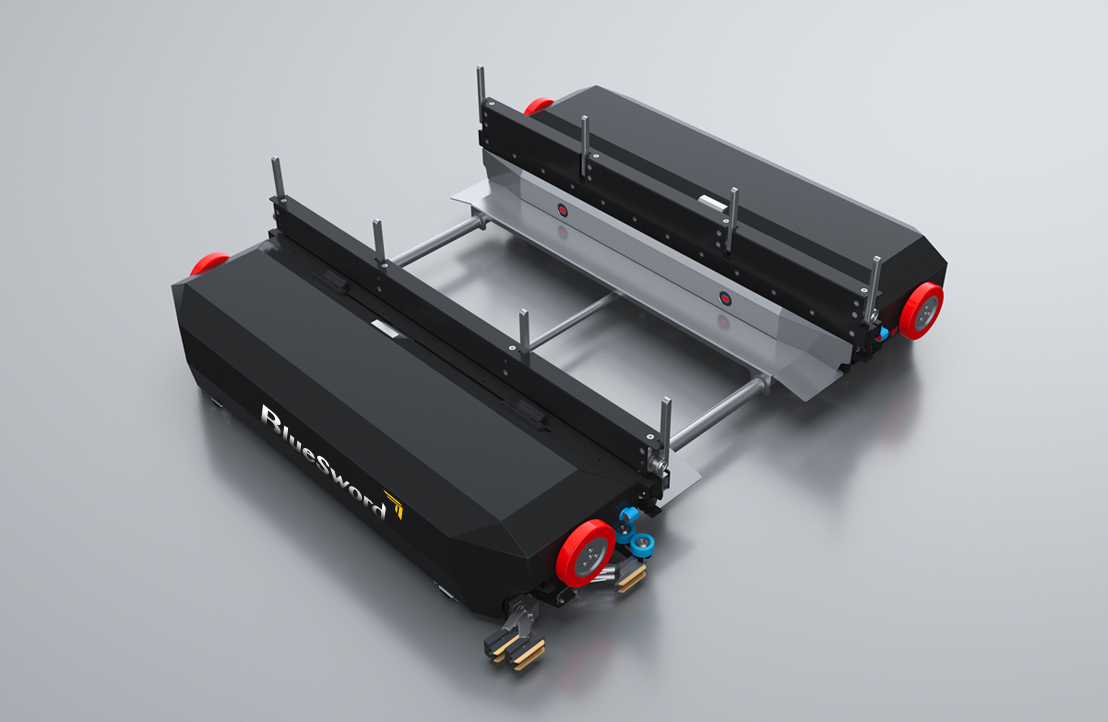

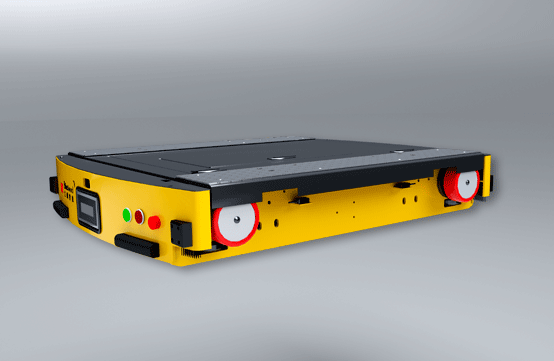

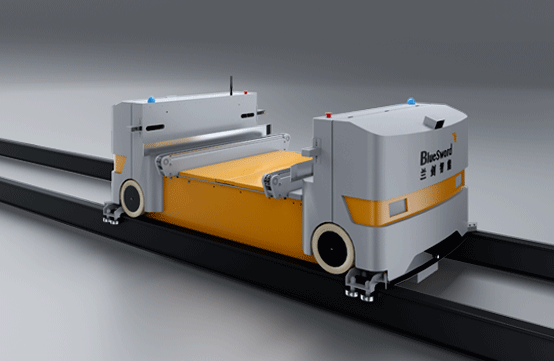

Travel speed: 5 m/s

Travel acceleration: 2 m/s²

Fork extend speed: 1 m/s

Fork extend acceleration: 1.5 m/s²

Machine weight: 80 kg

Load weight: 60 kg

Smart fork spacing adjustment range: 200 mm - 1,000 mm

Product type: single/twin carriage, single/double-deep

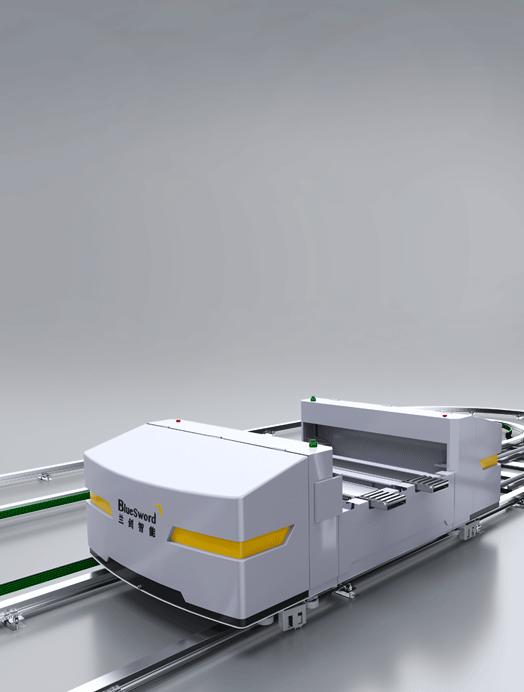

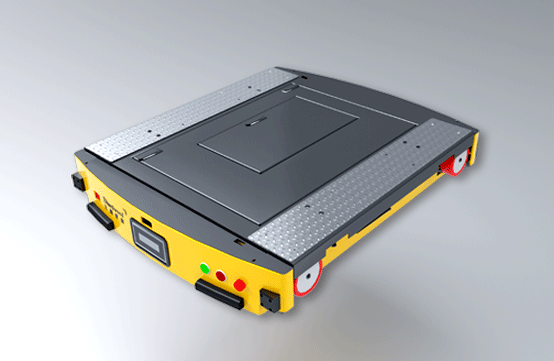

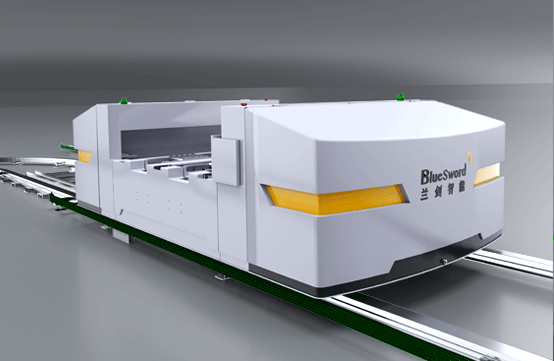

Complete the automatic handling, storage and retrieval, cycle-counting and Inventory arrangement of the whole pallet goods in the high-density warehouse.

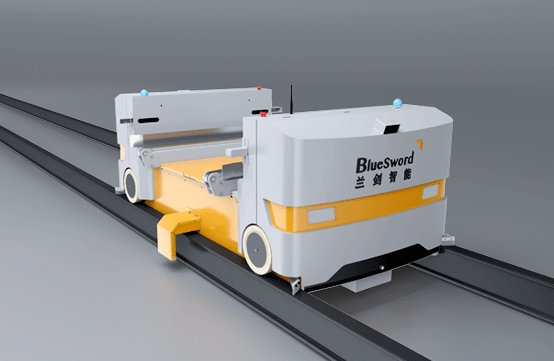

Travel speed 120 m/min.

Strong load capacity, with enhanced pop-up diverter design.

With handheld terminal control and fully automatic control dual-mode.

Meet the dual mode of manual handling with forklift truck and automatic handling of stacker crane.

Realize FIFO, FILO, single aisle multi-SKU storage, retrieval and other functions.

Automatic rescue in the shuttle board aisle.

Cross-docking between pallet level stations.

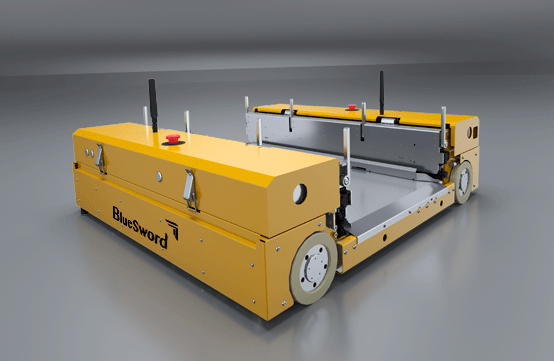

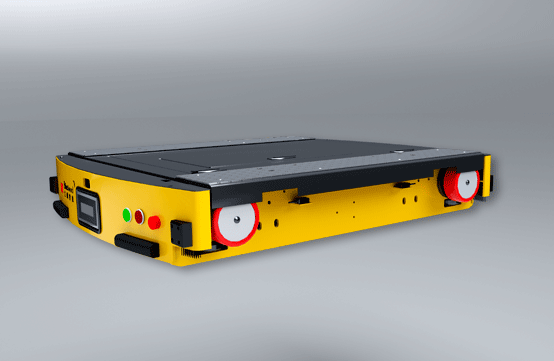

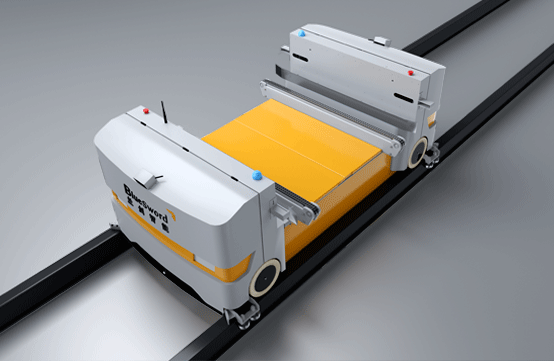

Travel speed: 300 m/min.

Travel acceleration: 1.5 m/s².

High safety, bar code precision positioning, accurate motion control.

Highly automated, high speed, high productivity to complete the whole pallet goods handling and divert.

Equipped with obstacle avoidance sensors to better ensure the safety of people and vehicles.

Multiple configurations are optional according to user needs.

Easy to install and debug, shorten the site construction time.

As a connection between racks and handling system, Ring RGV divert goods through chain conveyor.

Travel speed: 220 m/min.

Travel acceleration: 1.5 m/s².

Positioning accuracy: ±3 mm.

Algorithm optimal principle, optimize multi-vehicle scheduling.

Dual-drive + S-curve design, higher speed & greater stability.

Leak wave cable communication to prevent packet dropouts.

Remote control faulty vehicle, save time and labour.

Lidar obstacle avoidance to ensure the safety of people and vehicles.

The number of shuttles can be added according to the productivity.

Meet the demand of large gap connection, the goods transfer more stable.

Fill out your information, BlueSword will provide you professional service!