Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

The industry's quickly development, particularly with regard to whole-house customized products, which raise higher requirements and challenges to the automation level of logistics equipment.BlueSword consistently improves the warehousing automation capability of the household sector, secures the long-term high supply chain efficiency of consumers, and lower logistics costs with creative solutions and dependable automation equipment.

01

Wide range of products, Non-standardization, oversized, overweight, irregular, easy to damage.

02

Major potential safety risks, and the manual handling leads to increased product waste rate.

03

High labor intensity, low productivity, high error rate.

04

Large building area, low space utilization.

Factory Solution

Store Solution

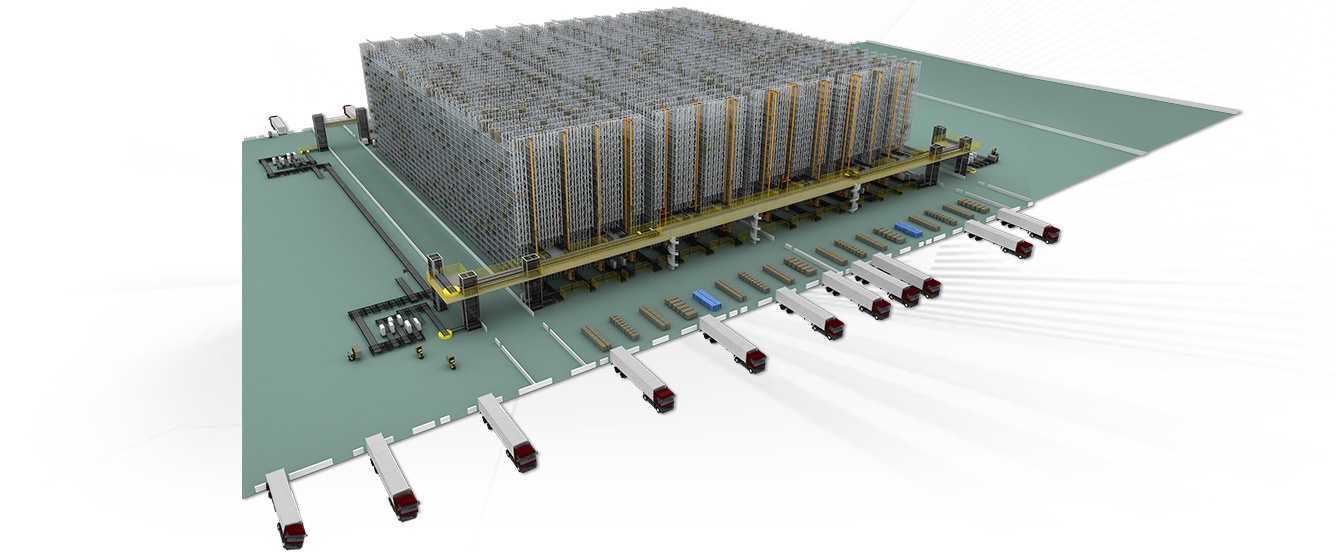

High Storage and Retrieval Solution

Automated Handling Solution

Automatic storage solution for panel warehouse and finished product warehouse at the factory;

Make oversized, overweight, super-wide storage objects, can achieve more stable, safer, more high-speed storage and handling.

In the logistics center of the store, according to the characteristics of diversified logistics attributes, Bluesword proposed a three-layer integrated solution;

Achieve automated storage and retrieval of all sized goods in the same warehouse.

Higher rack storage and retrieval solution with reach trucks AGV as the core equipment;

BlueSword reach trucks AGV maximum lifting height reaches 11.45 meters;

Integrating traveling, steering, fork lifting, gantry moving forward, retrieving, lateral shift, lean forward and lean back;

Without civil engineering or environmental reconstruction, realize "plug and play" unmanned upgrading.

Based on a variety of advanced artificial intelligence algorithms and automation technology, we provide the automatic handling solutions with AGV as the core equipment;

Using 3D visual system to realize the monitoring and correction of the pallet deflections;

Realize the pallet correction detection and fork picking, when the pickup can accurately detect the position and direction of the pallet, adjust the position according to the detection data, to achieve accurate pickup;

By detecting the the state of the pallet,It can ealize the abnormal pallet alarm.

Home furniture high automated storage and retrieval system

Automation

Material handling

45mm

Paperboard pallet

According to the area

Up and down pile

storage and retrieval

1 hole. 2 holes, 3 holes, even 4 holes

Fill out your information, BlueSword will provide you professional service!