Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

The particularity of the cold chain industry logistics system makes it more difficult to plan and implement, which requires the project implementation unit needs to solve the customer's real needs with targeted solutions and equipment. With innovative solutions and technologies to meet the market demand, BlueSword layout in the cold chain industry has been deep in meat, fruits and vegetables, medicine and other fields.

.jpg)

01

Under low temperature, personnel working environment is harsh,recruitment is difficult.

02

The particularity of special commodities needs high demand for customization.

03

Special goods in the cold chain have high requirements for safety and cleanliness.

04

Low temperature, high energy consumption, high humidity, frosting, fogging, clean.

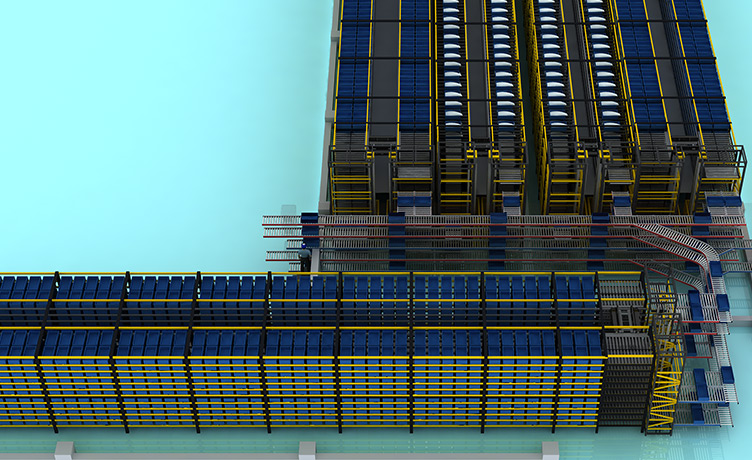

Cold Chain Case-level Solution

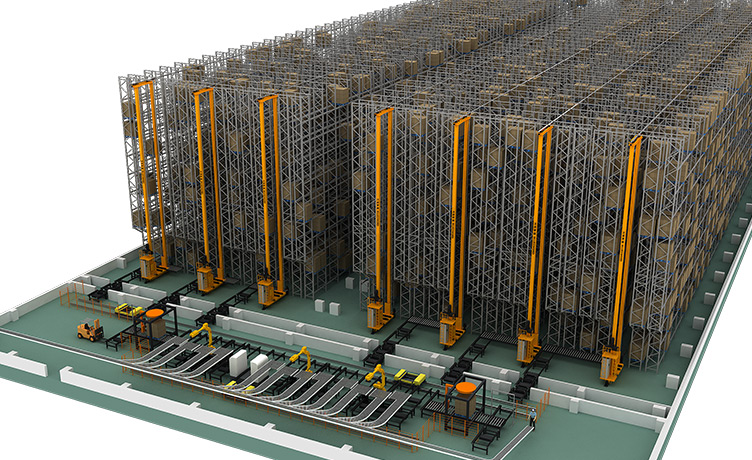

Cold Chain Pallet-level Solution

Using goods-to-person picking technology, productivity is greatly improved;

Separation operating environment, personnel work at room temperature, reduce occupational risks;

Using 3D vision technology to realize the automatic correction of the deflections and reduce the alarm rate;

Using fork variable size technology to realize original box storage and retrieval operations of different specifications.

Meet the National Standard, European Standard;

High-density storage, high-speed storage and retrieval, and high-precision processing;

AGV intelligent handling, can reach 11.4 meters of highest spot;

Vision algorithm solve the problems of blind storage, blind retrieval , cycle-count and so on;

Using Digital Twins to realize real-time monitoring, initiative operation and maintenance, preventive maintenance, improve the stability of the system;

Equipment selection shall meet the requirements of low temperature and high humidity.

Drugs automatic cold storage

Fruit automatic constant temperature storage

Food automatic cold storage

Food automatic fresh-food storage

High-speed

Case picking

Visual

Depalletizing and palletizing system

100,000+

Storage capability

Goods to person

Picking system

High cleanliness

Meet pharmaceutical grade requirements

Hommization

Separation of manual work environment

Meet 700+

Stores distribution

Goods to person

Picking system

High speed

Picking efficiency

Higher timeliness

Requirements

-18—25℃

Cold storage

10,000+

Storage spot

High-speed

Storage and retrieval

High density

Storage

Safety

Food-grade safety requirements

Meat

Multi-shuttle system

Production line

Connecting

High-speed

Storage and retrieval

Low temperature

High humidity and high greasy dirt

Food-grade

Mechanical material

Food grade

Flushing requirements

Fill out your information, BlueSword will provide you professional service!