Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Jun 20 /2022

share to

On June 16, the 2022 Gaogong Lithium Battery Intelligent Manufacturing Summit hosted by Gaogong Robot was successfully held in Changzhou. More than 1,000 industry experts and corporate executives attended the meeting. As a high-end brand of China's logistics technology, BlueSword was invited to attend this summit with its rich and mature innovative applications in the lithium battery industry. Business leaders discussed and discussed the transformation and upgrading of intelligent manufacturing in the lithium battery industry.

Dr. Shen Changpeng, Senior Vice President of BlueSword, delivered a keynote speech on "A Full Series of Intelligent Logistics Robots, Creating a New Engine for Lithium Battery Intelligence" at the meeting, and in the "roundtable dialogue" session with a number of industry experts and entrepreneurs to focus on the current focus Questions were discussed in depth.

Dr. Shen Changpeng said that the power battery manufacturing for the TWh era will face new challenges. No matter from the perspective of large-scale manufacturing and diversified cost reduction, the entire line of efficient and intelligent battery manufacturing will definitely be intelligent and unmanned. As an important support for realizing intelligence and unmanned operation, logistics robots have a great development space for application in the field of new energy.

Full process requirements & full range of robots

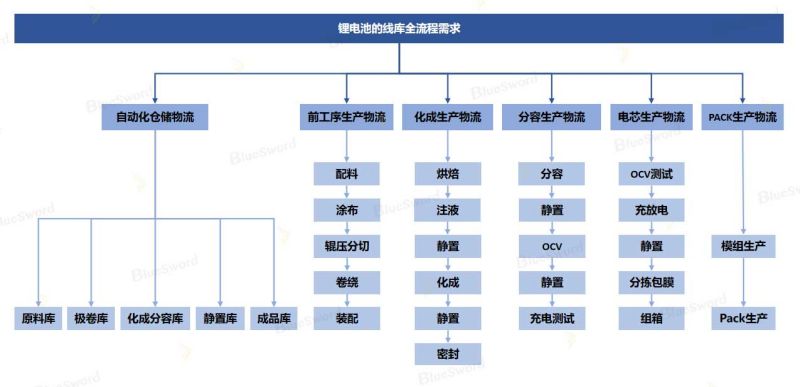

"In the face of the whole process demand of line warehouses such as pre-process production logistics, chemical production logistics, volume production logistics, battery cell production logistics, PACK production logistics, and automated warehousing logistics in lithium battery production and manufacturing, a full range of intelligent logistics robots are required. It matches with it. BlueSword full range of logistics robots can meet these needs." Dr. Shen Changpeng introduced.

BlueSword has been deeply involved in the field of logistics technology for nearly 30 years, and has always been committed to becoming the pioneer of high-end intelligent logistics robots in the world. At present, there are full-process general logistics robots such as warehousing robots, shuttle robots, handling robots, picking robots, depalletizing robots, packaging robots, and loading and unloading robots, as well as customized robots for specific products, such as tobacco and cigarette sorting robots, lithium battery components Special-purpose warehousing robots, etc.

In addition, the high integration of logistics robots and BlueSword digital twin system has truly realized the automatic and intelligent operation of the whole process of material unloading, warehousing, storage, picking, conveying, packaging, monitoring, and management, which can meet the needs of warehousing and distribution in the lithium battery industry. most of the needs of the link.

BlueSword Warehousing Robot

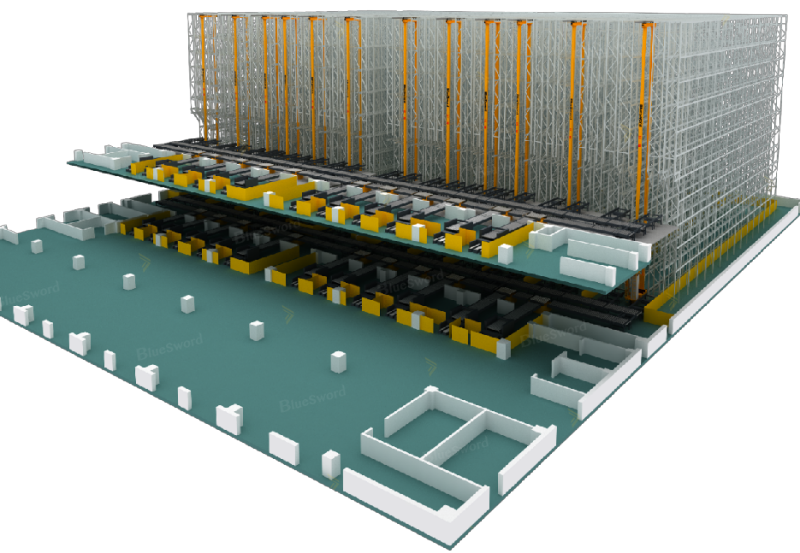

Single/double extension, straight/transit, multi-station, multi-load, multi-scene…

Ultra-high (45m three-dimensional warehouse application), ultra-fast, explosion-proof, low-temperature resistance...chemical operations, can meet most of the needs of the lithium battery industry warehousing and distribution links.

BlueSword Handling Robot

Turnover boxes/standard pallets, ground handling, high storage (up to 11.45m)…

Bezier curve control, laser SLAM navigation, 3D visual inspection…

Move Anything To Anywhere

BlueSword shuttle robot

Multi-station, multi-size, multi-scene, two-way/four-way…

Variable size, anti-static, waterproof oil fumes, low temperature quick freezing resistance...

Existing mature applications

Based on strong innovation capabilities and product advantages, BlueSword's full range of intelligent logistics robots have been used in raw material logistics, pole piece logistics, chemical component logistics, battery cell production logistics, battery cell finished product logistics, OEM logistics, etc. in the lithium battery industry. Mature application cases, and each has its own bright spots.

① Raw material logistics

· The raw material warehouse of a head enterprise that used high-speed stackers earlier in the industry

The BlueSword 240m/min high-speed stacker is applied, which improves the efficiency of inbound and outbound storage and brings substantial cost reduction and efficiency increase to the enterprise.

· Large-scale raw material warehouse of a head enterprise

The largest intelligent three-dimensional warehouse in the industry, with a total of 24 stackers, about 30,000 cargo spaces, and compatible with 3 different sizes of pallets.

· The raw material warehouse of a head enterprise where pallets of various sizes are mixed together

Compatible with the mixed storage of 4 sizes of pallets, and with ultra-high flexibility, it can seamlessly connect with the original warehouse systems of different manufacturers in the first phase of the project.

② pole piece logistics

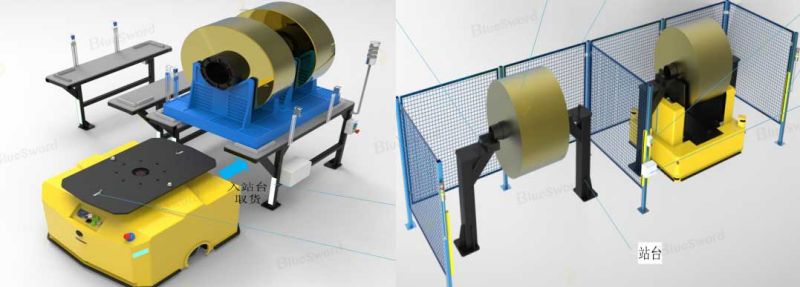

· A leading enterprise pole piece material production line handling system in the form of full SLAM

The latent small AGV with a load of about 1 ton and a large lift AGV with a load of about 2 tons are used. The anodes and cathodes of the large and small AGVs intersect each other. About 50 AGVs are dispatched at the same time, all of which use laser SLAM navigation, and the positioning accuracy is higher.

Pre-process pole piece AGV logistics handling system

· Handling and conveying system of pole piece material production line of a head enterprise compatible with various pallet sizes

Compatible with 4 kinds of pallets, about 2 kilometers of roller conveyor lines and about 40 AGVs, it realizes the perfect coordination of different kinds of pallets from raw material warehouse to production, as well as continuous and offline transportation.

③ Chemical composition logistics

· The chemical composition logistics system of a leading enterprise (storage + transportation + stacker)

BlueSword lithium battery industry-specific warehousing robot is very efficient in chemical composition and capacity. In a head enterprise's composition and capacity logistics automation system, BlueSword customized for customers to meet the requirements of capacity separation / load adjustment / high temperature (five sides Sealing plate, 60 ℃) static storage stacker, and double-layer roller conveyor, and includes DTS, smoke detector and other fire protection configuration.

④ Cell production logistics

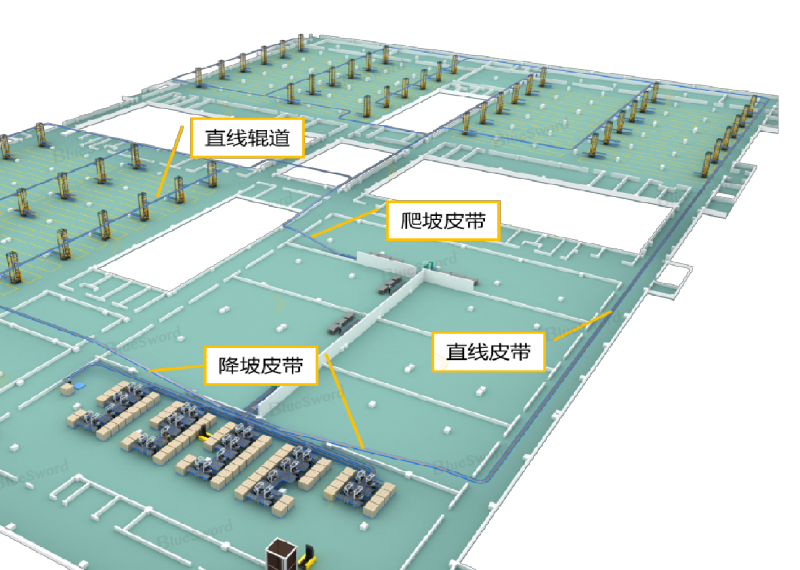

· Conveying system for cell production line of a leading enterprise (three-dimensional conveying)

More than 50 material box elevators are used in this project, and the conveyor line is responsible for the handling and lifting of finished products; and the aerial conveyor line adopts the combination of rollers and belts to reduce investment costs and bring huge practical value to the enterprise.

⑤ Logistics of finished cell products

· Cell finished product warehouse of a leading enterprise (explosion-proof + fire-fighting stacker)

The BlueSword stacker used in this project has the advantages of explosion-proof and fire protection, and has a very high safety level, and uses AGV to realize automatic connection.

⑥ OEM logistics

· Automated stereo library of FAW-Volkswagen and other automakers

BlueSword has created an intelligent three-dimensional library for many well-known car manufacturers. For example, the automated three-dimensional warehouse of FAW-Volkswagen (Tianjin) is an early application case of AS/RS and multi-pass system for the direct supply of auto parts to the main engine factory in the country; the company also built a full SKU zero for a new energy vehicle assembly workshop Component real-time direct supply line side system, etc.

Innovative applications of the future

Adhering to the core concept of "only innovation",BlueSword has been exploring full-scene unmanned applications in the lithium battery industry. Digital twin expansion applications, etc., enable intelligent manufacturing in the lithium battery industry.

① Fast sending and receiving

Raw material automatic unloading system of a well-known enterprise

Through the innovative application of BlueSword intelligent loading and unloading robot, automatic unloading can be realized in the future, and the unloading system is fully connected with the warehousing system, which reduces manual operations and greatly improves warehousing efficiency. The system has been successfully applied in the daily chemical industry, greatly reducing the unloading operation time.

② Multi-library in one

The fusion application of the post-process raw material library and the battery cell library of a leading enterprise.

With scale, the logistics automation system can exert its maximum value. In the future, BlueSword will innovate R&D to realize the multi-library integration application of raw material warehouse and cell warehouse in the lithium battery industry, and realize economies of scale. At present, it has realized the innovative application of multi-warehousing of raw materials such as storage materials, semi-finished products, finished products and packaging materials in the chemical industry.

③ Stereoscopic delivery

The distribution system of the new generation production line.

BlueSword has successfully developed a new generation of distribution system - the aerial shuttle robot three-dimensional conveying system, which realizes the free shuttle of the robot in the air, which not only saves the workshop space, but also avoids the interference of other work areas. It forms a workshop with other automation systems. "Three-dimensional traffic" layout for material handling within.

④ Digital twin to expand the application

Centralized control system of a leading enterprise

Most of BlueSword's smart logistics solutions of leading enterprise customers in the lithium battery industry are equipped with digital twin systems, of which the most widely used is the three-dimensional monitoring function, which can realize complete digital intelligent visualization. In the future, the BlueSword digital twin system will be further expanded in the lithium battery industry and applied to multiple scenarios such as planning and operation. In addition, it will be connected with the MES system to further improve business efficiency and maximize the value of the system.

In addition, the 45-meter-high super three-dimensional warehouse and the more than 30-meter-high super multi-passing warehouse of BlueSword Intelligent Super Future Factory have already jumped up, and will become the innovative benchmark for ultra-high intelligent logistics application scenarios in the industry. Robotic production will be realized after production. Intelligent manufacturing application scenarios of robots to provide customers with higher-quality logistics robots.

At present, the lithium battery industry has become the core of the global new energy industry and the main force of my country's "dual carbon" strategic goal. Chinese new energy companies are entering the global market strongly.

BlueSword will continue to explore the new value of logistics robots in the lithium battery industry, and efficiently empower the upgrade of lithium battery intelligent manufacturing; and rely on BlueSword's global service network to provide strong support for Chinese new energy companies to go overseas, and promote the development of national industries. Let the national industry shine in the world!

Fill out your information, BlueSword will provide you professional service!