Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Aug 24 /2021

share to

On July 15th, the 14th International Food Cold Chain Summit Forum 2021 was successfully held in Shanghai. The conference brought together nearly 400 industry authorities from food manufacturing, new retail e-commerce, chain catering, cold chain logistics and other fields.

Dr. Liu Peng, senior vice president of BlueSword Intelligence, was invited to attend and participated in the "brainstorming" session with several distinguished guests. Experts conducted in-depth exchanges on topics such as the new requirements of the cold chain industry for logistics technology and the new trends in the development of cold chain warehousing and logistics in the post-epidemic era.

New Development of Cold Chain Logistics

In recent years, the scale of the cold chain logistics market has gradually expanded, and the segmentation trend of fresh food e-commerce and pharmaceutical cold chain has become increasingly obvious. A sudden epidemic in 2020 has boosted the surge in cold chain warehouse business, forcing the logistics equipment industry to adapt to changing market demands at a faster innovation speed.

The new development of logistics technology in the cold chain industry is mainly reflected in the following aspects:

01 Unmanned cold storage

The cold chain industry has higher and higher requirements for quality control. Warehousing, picking, packaging, and delivery buffers must be handled in a standardized cold storage environment; and the special operating environment of the cold chain has caused difficulty in recruiting and retaining people. Such problems, coupled with the strong demand for non-contact operations after the outbreak of the epidemic, have made the unmanned cold storage become the general trend.

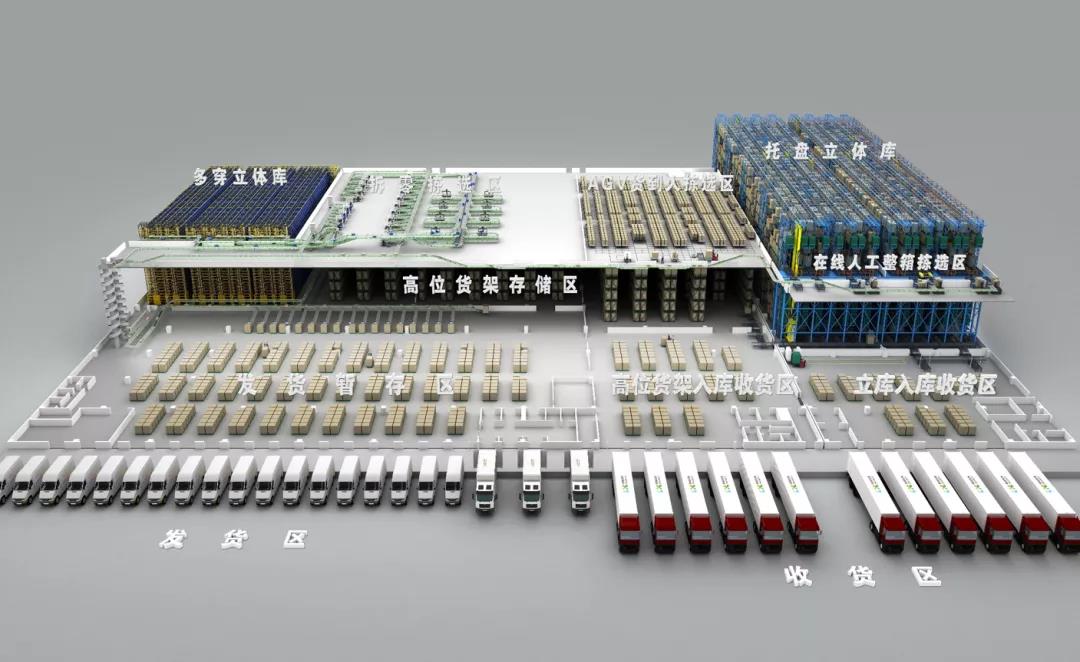

Unmanned cold chain warehouse built by BlueSword Intelligent

02 Fragmentation of business

The delivery business with the whole box as the unit is gradually increasing, and the stacker vertical warehouse suitable for the whole pallet operation can no longer meet the efficiency requirements. In addition, the reciprocating switching of the pallet by the stacker is also prone to waste of energy, especially in the freezer, in order to eliminate the heat generated by the movement of the equipment, the refrigeration needs to consume the same energy to deal with it. A new model to meet the fragmentation of business is waiting to be developed.

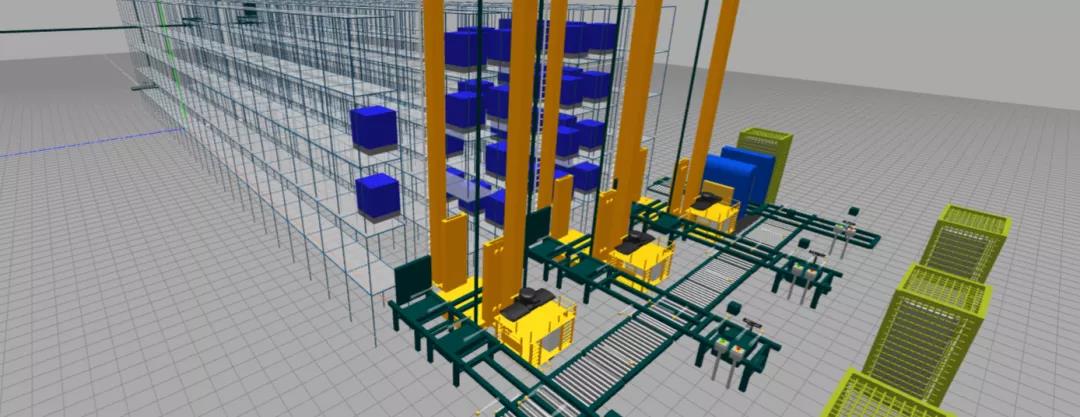

BlueSword multi-pass system is applied to low temperature cold storage

03 Technical Comprehensiveness

First of all, it is necessary to overcome the low temperature obstacle, so that any temperature environment will not affect the equipment performance and system efficiency; secondly, the fragile fresh vegetables and fruits, the meat frozen products that require high low temperature, and the biopharmaceuticals that need to strictly ensure safety, Vaccines, etc., must ensure low cargo damage in the storage and distribution links; in addition, the overall construction of the cold storage project is more difficult, and the integrator must have comprehensive planning, research and development, execution and after-sales capabilities.

BlueSword fresh food industry service case

04 Flexible and scalable

Cold storage systems should be flexible. To achieve flexible switching between cool storage and cold storage; to achieve flexible compatibility of product size, a single device can store and select products of different sizes; to fully consider the changing trend of business formats in the planning stage, in terms of facility layout, equipment selection, etc. Reserve space for upgrades.

05 Full traceability

With the help of information technology, the whole process information monitoring and traceability of goods, personnel, equipment and environment can be realized, and the closed-loop management of the whole cold chain process can be realized. This is not only based on the needs of epidemic prevention and control, but also a manifestation of the continuous progress in the level of intelligence.

Create new value for customers

Customer demand is the best direction for innovation. Based on the above-mentioned profound understanding of the development of the industry, BlueSword adheres to independent innovation and creates new value for customers with the new technology of intelligent cold chain logistics.

We have built automated cold storage unmanned warehouses for a number of cold chain industry customers.

· Design a honeycomb system suitable for dismantling and sorting operations to deal with fragmented business.

· The equipment is not afraid of -30 ℃ low temperature, and it operates stably in the cold storage.

· Has the ability to serve the whole process and consider the long-term for customers.

· The distance between the forks of the shuttle robot is self-adjusting, and the multi-size bins are stored together.

· The IMHS intelligent software system is fully managed and controlled, and the whole process is visible.

In addition, in order to cope with the impact of the epidemic, BlueSword has newly developed a 3D-SCADA system (three-dimensional data acquisition and monitoring and control system). This system adopts Digital Twin (digital twin) technology, through the three-dimensional visualization integration of the system platform, the whole scene 1:1 modeling. The 3D interface of the equipment is realized according to the on-site layout, and the logistics process is displayed linearly and intuitively in real time. What you see is what you get, making the operation more intuitive, simple and diverse.

The 3D-SCADA system has brought great improvement to the construction and service of cold chain logistics equipment.

During the construction process, the 3D-SCADA system can realize remote debugging, which greatly reduces the time loss and epidemic risk caused by the travel of debugging personnel. At the same time, the method of "expert consultation" can be adopted to concentrate the strength of many experts in various fields in the headquarters for centralized debugging, so as to improve the debugging quality and shorten the debugging cycle.

In the service process, the 3D-SCADA system can not only help the customer's equipment maintenance personnel to achieve rapid fault location and improve the response speed of equipment maintenance; The service goal of "Always be with customers".

In the context of epidemic prevention and control, the cold chain industry is facing unprecedented opportunities and challenges in the face of new market changes. BlueSword pursues logistics technology innovation with customer needs as the center, and helps the high-quality development of the cold chain industry.

Fill out your information, BlueSword will provide you professional service!