Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Media & Press

Aug 04 /2023

share to

Article | "Logistics Technology and Applications" Ren Fang

Only after thirty years of innovation, can we start again in the year we stand. "On June 1st, Wu Yaohua, the founder and chairman of BlueSword Intelligent Technology Co., Ltd., passionately stated at the 30th anniversary celebration of BlueSword Intelligent and the completion ceremony of the third phase of the Super Future Factory project." At the beginning of the thirties, our hearts remain unchanged. We will be a 'only innovation' logistics technology person, a logistics technology enterprise that can provide support for customers and take responsibility for society, and build a century old brand of BlueSword

BlueSword Intelligent, founded by Wu Yaohua, is a high-end logistics technology brand in China. It started as a logistics software brand in 1993 and was successfully listed on the Science and Technology Innovation Board of the Shanghai Stock Exchange in 2020. It has now become a provider of software and hardware integrated full process intelligent logistics systems and a manufacturer of a full range of intelligent logistics robots.

On the occasion of the 30th anniversary of the company's establishment and the completion of the third phase of the factory project, Wu Yaohua stated in an exclusive interview with the magazine "Logistics Technology and Applications" that since its establishment, BlueSword Intelligent has always adhered to the path of independent innovation, continued to deeply cultivate in the field of logistics technology, created many industry pioneers in software and hardware technology, filled the gap in domestic and foreign markets, and fully blossomed in domestic and foreign markets. At the age of thirty, BlueSword Intelligence will continue to adhere to the core development concept of "only innovation" and set out towards the goals of "century old BlueSword" and "world's BlueSword".

Anchor the original intention and adhere to the path of independent innovation

When it comes to the greatest experience of BlueSword Intelligence's growth along the way, Wu Yaohua summarized it in just eight simple words: keep your original intention and be down-to-earth!

For BlueSword Intelligent, its original intention is to become a Chinese national enterprise with independent innovation. It adheres to the path of self research, production, and implementation, adheres to the core development concept of "innovation only", and solidly produces products with revolutionary changes, promoting the continuous development of China's logistics technology.

If we look back at the growth process of BlueSword Intelligence in ten years, we can see that every step it takes is clear and firm.

1993-2003: Logistics system consulting planning+logistics software development and implementation+system integration

At the beginning of the establishment of BlueSword Intelligent, it was at the beginning of the entire logistics equipment industry in China, with logistics equipment mainly focused on purchasing and introducing foreign products. At this stage, BlueSword Intelligence focuses on logistics system consulting and planning, logistics software development and implementation as its core businesses, and provides customers with large-scale system integration services based on this in the later stages of the stage.

2003-2013: Independent development of specialized equipment

At that time, the Chinese tobacco industry was ushering in a golden decade of development. Due to the implementation of provincial-level industrial and commercial separation, the demand for logistics systems in the tobacco commercial system increased rapidly. Taking advantage of this opportunity, BlueSword Intelligent began to develop and produce automatic cigarette sorting lines for tobacco commerce, and thus rapidly expanded the market in the tobacco industry, laying the foundation for future industry expansion. At present,BlueSword Intelligent has achieved a fully automated solution for the entire process of cigarette unloading, warehousing, storage and sorting, sorting, coding, packaging, etc. Among them, the self-developed cigarette sorting line has been upgraded and iterated to the fifth generation.

2013-2023: General equipment development

After the first decade of development, BlueSword Intelligence has gradually discovered that it cannot provide a comprehensive solution solely for core equipment, and the value it creates for customers is very limited. Therefore, in the decade from 2013 to present, BlueSword Intelligent has not only started the production and manufacturing of general logistics equipment such as pallet stackers, but also innovated in services, such as creating an automated agency operation model with Vipshop, in order to provide better services to customers.

At this point, BlueSword Intelligent's business has covered all logistics system services such as consulting and planning, logistics software, system integration, specific product solutions, general product solutions, and automated operation.

The initial intention is easy to obtain, but it is always difficult to keep. It is easy to set a beautiful and ambitious goal, but it is difficult to firmly adhere to the initial beliefs like a rock. Wu Yaohua emphasized the four words' down-to-earth 'many times in the interview. He admitted that in the 30 years of development of BlueSword Intelligence, there have been restless moments in his heart, hesitations in the fierce competition of the industry, anxiety under the iron hooves of capital, and regrets that he did not start self research and production earlier... However, taking a path of independent innovation that is different from that of his peers is BlueSword Intelligence's unwavering commitment and perseverance.

Now standing at a new starting point, the original intention of Lan Jian Intelligence remains unchanged.

Only innovation can fill the gap in domestic and foreign markets

By forging ahead on the path of independent innovation, BlueSword Intelligent has not only achieved full coverage of the entire logistics business chain in 30 years, but also filled many gaps in domestic and even global markets in software and hardware technology, driving China's logistics technology forward continuously.

For example, the 3D logistics simulation system - the full lifecycle digital twin system - is one of them. In the early stages of the development of China's logistics equipment industry, there was no 3D simulation system with national independent intellectual property rights in the market, which was mainly introduced from countries such as the United States and the United Kingdom. BlueSword Intelligent, which started with software, broke through technological barriers and officially launched the self-developed 3D logistics simulation technology platform IMHS Simulation in 1997. With the development of software technology, BlueSword Intelligence has continuously iterated and upgraded it, and in 2021, it developed a full cycle digital twin system in the field of logistics technology.

兰剑数字孪生智能物流平台

“If the 3D logistics simulation system fills the gap in the domestic market, then we are confident to say that the full cycle digital twin system fills the gap in the world market Wu Yaohua further added that firstly, the system's business covers a comprehensive range, including both general equipment such as shuttle cars and stackers, as well as specialized equipment such as the cigarette production line independently developed by BlueSword Intelligent. Secondly, the system is not simply a replacement for offline and online simulation, but rather a full cycle simulation software that achieves full lifecycle services such as dynamic modeling, offline simulation, virtual debugging, online monitoring, and intelligent optimization.

Specifically, in the early planning stage of the project, 3D software is used to draw the design scheme and form an offline simulation system; In the mid-term implementation phase, it becomes a virtual debugging system again. After the single device is tested in the factory, it can be launched with one click on the project site, greatly reducing the debugging time of the entire system and providing quality interaction for customers in advance; In the later stage of use, it can also be an online monitoring system and a TPM device management system based on big data.

For example, the semi-automatic horizontal sorting line for tobacco is also a major innovative product. 20 years ago, BlueSword Intelligent and China Tobacco Group and its subsidiaries developed China's first semi-automatic horizontal cigarette sorting line. Afterwards, we successively developed semi-automatic and fully automatic waterfall sorting lines for cigarettes. Nowadays, the fully automatic waterfall sorting line for cigarettes has been widely used in the tobacco industry. Through mutual promotion and common growth with industry friends, BlueSword Intelligent is driving China's tobacco cigarette sorting system to reach an international leading level.

On site of a project at Vipshop

In addition, BlueSword Intelligent has also built a 45 meter high pallet stacker silo system and a 35 meter high material box multi-layer shuttle truck silo system. In addition to achieving excellence in software and hardware technology, BlueSword Intelligent has also built multiple industry benchmark projects. For example, working together with Vipshop to build the world's largest e-commerce logistics system, there are nearly a thousand shuttle cars, nearly 500000 turnover boxes, tens of millions of SKUs, and a daily order processing volume of up to 900000 during peak business hours in Vipshop's Southwest Logistics Center. It is precisely based on these innovative and efficient logistics systems that BlueSword Intelligence has assisted the factories of two leading enterprises in successfully applying for the "Lighthouse Factory".

BlueSword Intelligent Super Logistics Center: 45 meter high and super high stacker system&35 meter high and super multi threading system

Only innovation means meaningful and valuable innovation, truly saving costs and creating value for customers. "Wu Yaohua pointed out the significance of BlueSword Intelligent's continuous innovation. He firmly stated that BlueSword Intelligence, with innovation as its soul, will always lead the industry in technology, high-quality products and services, continuously create mature and effective intelligent logistics overall solutions for customers, and help them achieve high-quality development.

Comprehensive energy storage rooted in the domestic market

In 2022, the total amount of new orders signed by BlueSword Intelligent reached 1.167 billion yuan, achieving a revenue of 915 million yuan, an increase of 51.59% compared to the previous year. Through continuous accumulation and sedimentation, the achievements of BlueSword Intelligence are evident to all, and it has also built strong competitiveness.

1. A comprehensive and intelligent product series. BlueSword Intelligence is mainly engaged in the research and development, design, production, sales, and service of intelligent logistics systems with intelligent logistics robots as the core. Wu Yaohua emphasized that BlueSword Intelligent hopes that the projects it creates can become a century old project. Therefore, as a logistics system solution provider, one must have their own core equipment in order to be responsible for the quality and quality of the project.

Based on the ultimate pursuit of technology and products, as of December 31, 2022, BlueSword Intelligent has 311 independent intellectual property rights, including 76 invention patents, 159 utility model patents, 21 design patents, and 55 software copyrights. Its independently developed and produced intelligent logistics robots cover almost all business processes, including warehousing robots, shuttle robots, handling robots, picking robots, loading and unloading robots, palletizing robots, aerial robots, etc; And many intelligent warehousing and logistics automation systems have been built with logistics robots as the core: a tray level dense storage and distribution integrated system with warehousing robots as the core, a material box level dense storage and distribution integrated system with shuttle robots as the core, a specific commodity fully automated picking system with picking robots as the core, and an automatic loading and unloading system with loading and unloading robots as the core, And other automated and intelligent systems that are highly integrated with logistics software centered around digital twin platforms.

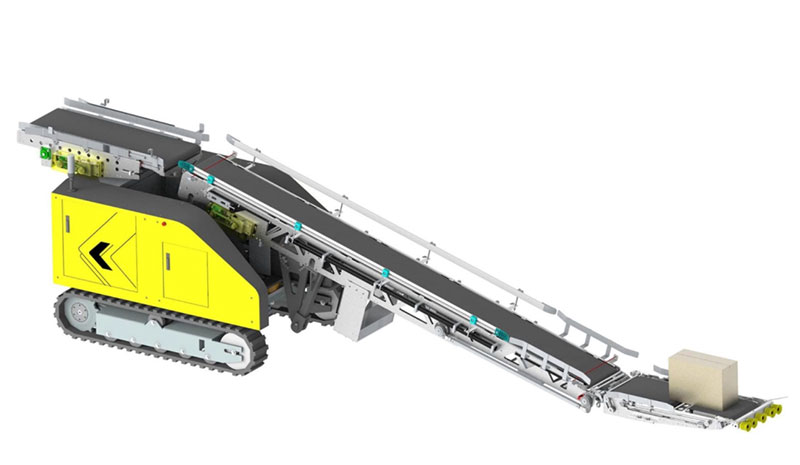

Lan Jian Intelligent Loading and Unloading Robot "Asian Elephant"

In 2023, BlueSword Intelligent launched three new logistics robot products: a new generation of intelligent stacking machines with functions such as intelligent shelf detection, anti shaking algorithm, and intelligent inventory; A fully servo tray conveying system that is more energy-efficient, power-saving, and more stable, capable of withstanding a load of 1500kg, which will bring revolutionary changes to the conveying line; And the "Asian Elephant" intelligent loading and unloading robot, which can operate continuously and flexibly, adapt to the box type, and have an efficiency of 700-900 boxes/hour.

In addition, BlueSword Intelligent has also launched a disruptive and innovative all gear four-way shuttle, which replaces traditional chain transmission solutions with a gearbox. Not only does it have more precise control, but it also has a thinner body and significantly improved performance.

2. Industry leading production capacity supporting facilities. In order to adapt to the rapid development of the company, better meet the differentiated product needs of customers in different industries, and break through production capacity bottlenecks, BlueSword Intelligent is firmly moving towards intelligent manufacturing in 2021, expanding the original logistics equipment production base, and building a super future factory covering an area of 300 acres. This is not only one of the largest specialized logistics equipment production bases in China, but also the 45 meter high ultra high stacker system and the 35 meter high ultra multi threading system are innovative benchmarks for ultra high intelligent logistics application scenarios in the industry field.

It is reported that with the completion of the third phase of the BlueSword Intelligent Super Future Factory project, it will further expand production capacity, shorten supply time, and improve customer demand response ability in the future; The scale of a single building area exceeding 35000 square meters will also become the largest in the industry.

3. A highly cohesive team of highly skilled talents. As one of the earliest researchers in the field of logistics engineering in China, Wu Yaohua has long been committed to theoretical and technical research in the logistics field, including macro and micro logistics system planning, enterprise logistics information system construction, logistics software design, and high-end logistics technology equipment research and development. He has more than 30 years of research experience. At the same time, Wu Yaohua also serves as a professor and doctoral supervisor at Shandong University, cultivating a large number of outstanding talents in the field of logistics technology in China, many of whom have become core team members of BlueSword Intelligence.

3. A highly cohesive team of highly skilled talents. As one of the earliest researchers in the field of logistics engineering in China, Wu Yaohua has long been committed to theoretical and technical research in the logistics field, including macro and micro logistics system planning, enterprise logistics information system construction, logistics software design, and high-end logistics technology equipment research and development. He has more than 30 years of research experience. At the same time, Wu Yaohua also serves as a professor and doctoral supervisor at Shandong University, cultivating a large number of outstanding talents in the field of logistics technology in China, many of whom have become core team members of BlueSword Intelligence.

Based on the continuous construction of various capabilities, BlueSword Intelligence has formed significant advantages in industries such as aerospace, communication equipment, tobacco, medicine, new energy, engineering machinery, food, e-commerce, etc. In 2022, sales in the aerospace and tobacco industries exceeded 100 million yuan. In the field of new energy, while continuously obtaining orders in the raw material warehouse and electrode production processes, we have also developed specialized stacker equipment for the chemical composition and capacity division process and successfully implemented it. In the future, BlueSword Intelligent will closely follow the "14th Five Year Plan" and continue to expand into new industries, such as airports, aerospace, chemical fiber, fast moving consumer goods, semiconductors, agriculture and animal husbandry, lithium battery industry, military industry, etc.

Looking globally and becoming the world's Lan Jian

Based on the development strategy of dual market and dual line development both domestically and internationally, BlueSword Intelligent not only deeply cultivates the domestic market, but also actively expands overseas markets. In 2018, it successfully exported a complete set of logistics systems to Japan. At present, BlueSword Intelligent's complete set of high-end logistics equipment has been successfully exported to overseas developed countries such as Japan, the United States, Germany, and has gradually grown into an excellent national brand in the field of logistics technology in China through various efforts.

On the one hand, conducting rich international academic exchanges and project research. As early as 1999, Wu Yaohua began exploring and exchanging ideas with the North American logistics engineering community, and conducted in-depth technical discussions on logistics automation with leading enterprises in various industries such as Germany, Singapore, and Japan, to understand the development trends of logistics technology from around the world.

On the other hand, I have participated in a large number of world-class logistics engineering projects. For example, collaborating with Georgia Institute of Technology to build a world-class logistics center for chain pharmacies, creating a real-time interactive raw material warehousing system for Procter&Gamble with production lines, and discussing a 3D cargo to person system based on multi-layer shuttle technology with Amazon.

A well-known cross-border logistics service provider, the Los Angeles E-commerce Logistics Center, USA, has a person to person picking system

In addition, Liangjian is a high-quality overseas exhibition. Since 2018, BlueSword Intelligent has been making frequent appearances at international logistics exhibitions every year, such as the Hanover Industrial Expo, ProMat Show in the United States, and Smart Logistics Show in Tokyo, Japan, allowing customers in key markets to witness and experience BlueSword Intelligent's strength firsthand.

Through multidimensional efforts, BlueSword Intelligence has obtained many world-class certifications, such as international T ü V agency CE certification and international SCL agency RMI certification. Through exports, the product quality and technological content of BlueSword Intelligence have been further forged and improved, and in turn, a threshold has been established in the domestic market. "Wu Yaohua looks forward to saying," BlueSword Intelligence continues to empower the world's intelligence warehouse with 'Chinese wisdom, Chinese speed, and Chinese solutions'. In the future, it will take more' Chinese solutions' to the world and become the 'world's BlueSword'.

Deeply researching intelligent technology to create a century old brand

The age of 30 is a crucial milestone. In China, we already have a certain history, but compared to the world's century old enterprises, we are still very young and need to accumulate and precipitate. "Wu Yaohua candidly said," The top ten global logistics equipment industry are basically century old enterprises, and I still hope to see BlueSword Intelligent walk alongside them, and even surpass them

Next, BlueSword Intelligent will continue to firmly follow the path of self research and self production, focusing on intelligent technology as the development direction, accelerating the pace of iterative optimization, and achieving upgrades from automation to intelligence. In Wu Yaohua's view, future intelligent logistics products and systems will not only undergo revolutionary changes, but more importantly, create more value for customers and lower costs through innovation.

BlueSword Intelligence has provided its own thoughts on what the new generation of logistics systems will look like:

One is the logistics of 'nothing'. Usually, within a logistics center, there are at least six operational processes involved, including unloading, palletizing, handling, warehousing, unstacking, and sorting. In the future, through the innovation of logistics systems, it will become only three processes: unloading, sorting, and packaging. The initial idea of BlueSword Intelligence is to store original boxes (such as wooden or iron boxes) that do not require pallets on shelves, cancel pallets, and perform operations such as combining and reversing pallets; And it can achieve two-layer or three-layer stacking of turnover boxes, further improving storage density and bringing more value to customers. It is reported that the system has already implemented some functions. For example, in a project in the US e-commerce industry, BlueSword Intelligence can achieve a maximum efficiency of 8000 boxes/hour in and out of the warehouse through stacking technology (the project has 8 multiple tunnels).

The second is "no one" logistics. At present, BlueSword Intelligence has developed intelligent devices that can be applied in various stages, and has taken the lead in achieving "quasi unmanned" warehouses in industries such as tobacco, e-commerce, and medicine. In the next 30 years, BlueSword Intelligence will strive to transform "machines" into "robots", equip a large number of logistics equipment with "eyes" and "brains", so that they can obtain more information and think like humans, improve efficiency, and avoid risks. The logistics system will also transform from a system handled by humans to a system handled by robots.

The third is logistics without electricity. The research and development focus of BlueSword Intelligence is not only on improving efficiency and quality, but also on helping customers reduce costs such as operation and maintenance costs. In the future, with technological progress, on the one hand, through energy feedback and other means, the electricity consumption of logistics systems will be reduced; On the other hand, through methods such as warehouse photovoltaic power generation, it can meet the electricity demand of the entire warehouse equipment, so that the entire logistics system will hardly require external electricity.

Wu Yaohua revealed that if the development plan is specific to the next five years, BlueSword Intelligent will focus on three things: first, achieving full industry coverage; The second is to achieve the integration of products and products; Thirdly, we will collaborate with industry strategic partners to achieve large-scale customization. He said, "The goal of BlueSword Intelligence is to become the number one in the industry, but it has never thought about defeating anyone. Instead, it is to become a better self and do things that can promote industry progress. When a company makes a significant contribution to the development of the industry, it naturally becomes the number one in the industry and truly becomes a respected enterprise

Be ambitious, stand tall at thirty, thirty is all! The flourishing Lan Jian Intelligence has embarked on a new journey, setting sail for a wider world.

Postscript:

At present, the logistics equipment industry is undergoing rapid transformation. Due to the large technological span and basic customization of logistics system projects, it is difficult to achieve large-scale replication and development like in industries such as automobiles. In addition, the complexity of market demand, changes in the external environment, as well as the impact of the epidemic and capital, the development situation of the entire industry is relatively severe.

In this situation, the flourishing posture demonstrated by the youthful Lan Jian Intelligence will to some extent stimulate the industry's development momentum and vitality to overcome difficulties. Ultimately, as expected by Wu Yaohua, the industry will work together to build a new ecosystem of digital intelligence logistics, promote the entire logistics equipment industry to a higher level, welcome great development, innovate in the future, and contribute to the upgrading of global logistics intelligence.

Fill out your information, BlueSword will provide you professional service!