Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

May 05 /2022

share to

Editor's Note:

Dr. Liu Peng, Senior Vice President of the Company

Accept an exclusive interview with SmartNet and share

In the wave of intelligent upgrading

BlueSword Intelligent's Logistics Technology Innovation and Practice

Source of the following article: Intelligent Network 2025china.cn

In recent years, with the continuous spread and repetition of the epidemic, people's life rhythm has been disrupted, and the "last mile" logistics has become a practical problem closely related to daily life. And if you put the perspective on the dimension of industry, whether it is manufacturing such as automobiles, new energy, shoes and clothing, 3C electronics, or consumer industries such as retail and e-commerce, the goals of energy saving and efficiency increase and emerging needs such as personalized manufacturing are superimposed The digital and intelligent upgrade of warehousing and logistics has become an important trend in industrial development.

Data from relevant institutions shows that China's smart logistics market will reach 647.7 billion yuan in 2021, a year-on-year increase of 10.9%, and it is predicted that it will reach 699.5 billion yuan in 2022. Among them, the manufacturing industry, which is an important pillar industry of the national economy, will also have a smart logistics market scale of 100 billion. With the continuous development of the manufacturing industry, the problems of raw material management, work-in-progress management, finished product management, etc., are becoming more and more prominent.

For example, there are a large number of parts and components with inconsistent box specifications in the automotive industry, which are complicated and prone to waste; the shoe and apparel industry has a large number of SKUs, which makes warehousing, picking, and distribution difficult; materials in the 3C electronics industry are scattered, which is easy to cause low production efficiency and material loss. The sluggishness and the long cycle of materials are all common, and these common pain points are becoming the restrictive factors for the traditional manufacturing industry to move towards intelligent manufacturing.

Dr. Liu Peng, senior partner and senior vice president of BlueSword Intelligence, believes that logistics technology innovation is an effective way to solve the above manufacturing problems. Through digital and intelligent smart warehousing technology, smart logistics can be upgraded, and the level of refined and intelligent management of manufacturing raw materials, work-in-process, semi-finished products and finished products can be improved, thereby greatly improving inventory inaccuracy and sorting caused by manual operations. Problems such as low timeliness and poor picking accuracy enhance the competitive advantage of the enterprise's own supply chain; at the same time, it reduces the labor cost of the enterprise and improves the utilization rate of the warehouse, so as to create practical and huge economic value for the manufacturing enterprise.

Digital twins push the boundaries of logistics

How to intelligently upgrade traditional warehousing technology? In the process of thinking, BlueSword has found a new answer through continuous research and development and innovation of logistics technology in combination with the emerging business needs.

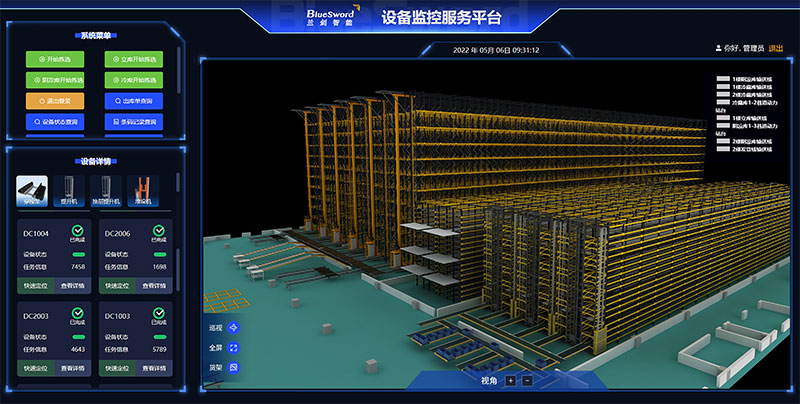

BlueSword Intelligent innovatively introduced the concept of digital twin into the field of logistics, and independently developed an integrated smart logistics system with digital twin as the core covering the entire life cycle of logistics, including warehousing, sorting, distribution, management, and assessment. The system is a full-process 3D logistics platform that integrates functions such as dynamic modeling, virtual simulation, offline debugging, 3D monitoring, predictive maintenance, and intelligent optimization. It can meet customers' full value from planning and design to equipment operation and maintenance. chain requirements.

For example, the system modeling and virtual simulation software applied in the program planning and design stage is different from traditional digital simulation or animation, but is based on 1:1 high-precision modeling based on real equipment parameters and real application scenarios, and then imports real inventory by importing real inventory. , real inbound and outbound orders and other data, find out the bottleneck point of the efficiency of the scheme, and carry out effective optimization to give the optimal end-to-end solution.

In view of the pain points such as long debugging time in the construction stage, the offline debugging software developed by BlueSword Intelligent can preview the entire process by establishing a simulation database and simulation signals before the equipment enters the site, and quickly locate potential risks; software debugging and hardware construction are parallel, shortening the time The on-site commissioning cycle reduces the time and cost of waiting for customers. Especially in recent years, the spread of the epidemic has brought many challenges to offline work. Remote offline debugging provides customers with an ideal choice. Only this stage of debugging can reduce the construction period by 10% to 30%, reducing costs and increasing customers. key point of effectiveness.

Now, BlueSword intelligent digital twin system has been successfully applied in many projects. With the help of the 3D-SCADA three-dimensional monitoring platform in this system, customers can realize the three-dimensional visual operation and maintenance of the entire scene through various terminals such as PC, mobile phone or tablet. And based on the system's self-learning predictive maintenance function, when an abnormal situation occurs in a certain equipment or a link in the system, the system can also proactively warn and prompt customers, so that customers can find problems and troubleshoot intuitively, and truly realize Make complex operations management "what you see is what you get".

Relying on the self-developed intelligent software system and self-developed and self-produced intelligent hardware products, BlueSword Intelligent already has the ability to provide end-to-end overall solutions, which is also the basis for its strong competitive advantage in the field of intelligent warehousing and logistics automation. "We started with high-end logistics software, and in recent years, we have gradually established more and more powerful high-end logistics equipment intelligent manufacturing capabilities, and have the advantage of a full range of intelligent product chain in the field of logistics! Through the integrated wisdom based on products and services For the overall logistics solution, we are committed to bringing more value-added services and extended value to customers, helping customers go further on the road of intelligent manufacturing and upgrading!" Dr. Liu Peng said proudly.

The super factory of the future makes logistics "one more kilometer"

As the company's No. 1 project, BlueSword Smart "Super Future Factory" has attracted much attention from the industry since its construction started in 2021. As early as 2014, BlueSword Intelligent has built and put into operation a high-tech logistics equipment and technology industrial park. With the continuous growth of business volume in the future, BlueSword Intelligent plans and builds a "super future factory" in advance, so as to expand the production capacity of its own products, which can not only improve the ability to guarantee the needs of existing customers, but also support the needs of more industry customers The effective coverage of BlueSword will help BlueSword Intelligence develop to all fields and scenes.

If you walk into this under-construction factory, the first thing you will see are two "steel behemoths": a 45-meter super three-dimensional warehouse and a 30-meter super multi-storey shuttle system, which makes the industrial scene full of shock sense of the future. Among them, the high-precision shelves of the super three-dimensional warehouse have leaped high, the ultra-high storage robot is also being installed and debugged, and the multi-pass system is under simultaneous construction. In the future, it will become BlueSword's own super logistics center.

In addition, BlueSword Intelligent's unique pulsating shuttle robot production line, high-precision shelf automatic production line, AGV system, tray & material box conveying system, EMS aerial robot system, etc. have also settled in the "Super Future Factory". It is the core of this super factory using robots to produce robots, and it also shows the strength of BlueSword Intelligence in intelligent manufacturing.

At present, the main body of the Super Future Factory has been completed, some production lines have been put into production, and other production lines that are being installed and commissioned will be put into use in 2022, and all of them can support the order scale of 2 billion yuan, doubling the current production capacity. . "The logistics overall solution manufacturer must have the ability to develop, produce and implement the main logistics equipment, which is the basis of the overall solution." Dr. Liu Peng said, "We hope that through the construction and continuous improvement of the super future factory, we will be able to We will continue to provide high-quality products, high-quality services and high-end overall solutions for the leading customers in the world's high-end markets."

And this is not only an important step for BlueSword Intelligent to become a global leading enterprise of high-end intelligent logistics robots, but also a solid foundation for BlueSword to implement its corporate mission of "providing China's answers to the world's smart warehouses"!

Fill out your information, BlueSword will provide you professional service!