Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Media & Press

May 30 /2022

share to

In recent years, the scale of China's petrochemical industry has continued to expand, and it is in a critical period of turning to high-quality development, which puts forward higher requirements for the intelligent level of warehousing and logistics. How to use advanced logistics and warehousing technology to help the petrochemical industry realize the intelligent upgrade of warehousing and logistics? In this regard, Dr. Liu Peng, senior vice president of BlueSword Intelligent Technology Co., Ltd., shared relevant information in an interview with industry media.

The following is the interview transcript:

1. What are the requirements for the construction of automated three-dimensional warehouses in petrochemical enterprises?

Dr. Liu Peng:

From the perspective of the industry, the entire petrochemical industry has put forward higher construction requirements for automated stereoscopic warehouses.

First, the scale is relatively large.

Generally, the number of automatic warehouses and pallet warehouses in the petrochemical industry is more than 20,000, the number of lanes is more than 20 lanes, and the flow rate is more than 1,000 pallets/hour. Such demand is also leading in the entire manufacturing industry.

Second, be steady.

Most of the goods in the petrochemical industry are bagged and packed in heavy film, which requires our storage equipment, handling equipment, and transfer equipment to be absolutely stable and absolute when handling these goods. Safety, which is a high requirement for the equipment itself, is also a requirement in response to the characteristics of finished materials in the petrochemical industry, which requires a lot of motion control technology and flexible scheduling technology.

Third, an end-to-end solution.

From the automatic palletizing off the production line, to the storage sorting inside the warehouse, to the delivery of trains or cars at the back end, and the entire informatization, the entire physical logistics and information flow must run through. Therefore, an end-to-end overall solution is needed, and this solution needs to be implemented with high quality within a reasonable construction period in order to meet the real needs of the petrochemical industry for automation.

To sum up, large scale, high security and stability requirements, and integrated software and hardware solutions are the requirements for the construction of automated stereoscopic warehouses in the petrochemical industry.

2. Technical difficulties and countermeasures for petrochemical enterprises to apply unmanned forklifts?

Dr. Liu Peng:

Unmanned forklifts have been widely used in many industries. For example, we have applied a high-fork AGV with a height of 11.45m to the top home furnishing companies in the world. For example, we have implemented automatic loading and unloading of unmanned forklifts for transformers of two tons or more in the power industry.

The application of BlueSword intelligent unmanned forklift in the household and power industry

On the basis of a large number of applications, there are still certain technical difficulties in the application of unmanned forklifts in the petrochemical industry, and these technical problems need to be well solved. In this regard, we also have some relevant countermeasures.

First, the floor problem.

Because the cargo itself is relatively heavy, whether traditional forklifts or unmanned forklifts, there are relevant requirements for the floor during operation. Therefore, we suggest that when applying these technologies, we should first carry out some basic transformations on the floor to meet a requirement for the application of unmanned forklifts.

Second, the cargo stack is high.

The cargo stacking shape in the petrochemical industry is relatively high, and sometimes two pallets are stacked. This is how to achieve precise positioning, stable handling, intelligent pallet jack recognition and intelligent precise fork feeding when forklifts pick up and place goods. Very demanding. In this case, we can use technologies that have been maturely applied in other industries such as home furnishing and electric power, such as laser SLAM navigation technology, flexible control technology based on high-order S-curves, and precise jack recognition technology based on visual recognition algorithms. , to achieve a comprehensive application, so as to achieve accurate, stable and efficient picking and placing of unmanned forklifts.

The application of BlueSword intelligent AGV advanced technology

3.Dr. Liu Peng: How do petrochemical companies upgrade their logistics information systems?

Combined with some typical scenarios in the petrochemical industry, I will share some thoughts on the informatization construction or informatization upgrading of the petrochemical industry.

When it comes to upgrading, we must first meet a foundation, that is, to allow all our materials and vehicles of all materials to have an electronic identity. Of course, this can be achieved by means of RFID tags, or by means of barcodes and labels.

Second, through a lot of customer research, we found that many systems are already available, such as packaging machine systems, production line systems, warehousing systems, shipping systems, vehicle scheduling systems, and so on. The second foundation is that it is necessary to open up the data link between these systems and connect the information islands one by one in order to have the conditions for further informatization upgrade.

Based on these two foundations, I think two things should be done:

First, it is necessary to build an end-to-end set of scheduling strategies and algorithms for materials, personnel, equipment, and vehicles. Through this algorithm, the above man, machine, material, method and environment can be combined with the business to achieve an accurate scheduling and efficient operation.

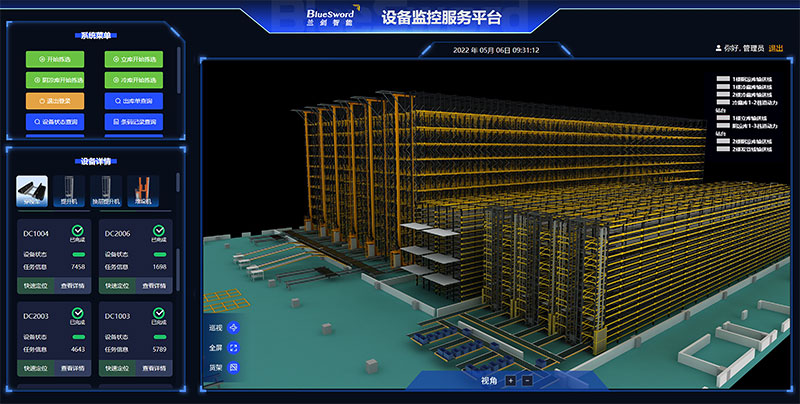

Second, it is necessary to apply the digital twin technology of the most advanced logistics in the manufacturing industry. Through 3D visualization, the operation of the entire system can be displayed on a computer, mobile phone or other terminal in real time, so that the operation and maintenance personnel can efficiently and accurately locate the position of the operation and maintenance point, and it can also allow the management personnel to be the first to use the 3D method. Time to master all the data of the enterprise.

4. As the petrochemical industry enters a stage of high-quality development, what opportunities and challenges are there for logistics equipment companies?

Dr. Liu Peng:

The petrochemical industry has developed very fast in recent years, which has indeed brought many challenges to logistics equipment companies.

First, the petrochemical industry has a relatively large stock, so more and more companies are building high-level automated three-dimensional warehouses exceeding 24m.

Second, the flow requirements of the petrochemical industry are relatively high, so a faster high-speed stacker is required, generally exceeding the horizontal running speed of 180m/min. Only in this way can the petrochemical industry meet the needs of such high flow.

BlueSword intelligent high-speed stacker

The goods in the petrochemical industry are almost all bagged products, and they are all packaged in heavy film. From the perspective of cost reduction, the owner does not want to wrap the film. Therefore, this requires that the stacker and the loop through need to have a higher-order S-curve control technology to achieve safe and stable picking and placing of goods. At the same time, we see that more and more owners are exploring the application of European standards while meeting the national standards to build the entire logistics automation system with higher security.

Third, the petrochemical industry has relatively tight requirements for construction periods, which requires logistics equipment companies serving this industry to have end-to-end overall services from design, self-research, self-production, and self-implementation. Only companies with such capabilities can truly understand the device, truly maximize the value of the entire system including the software, and bring customers a higher and better experience.

Our BlueSword started as a WMS in 1993, and has gone through nearly 30 years of development. Our 300-acre super factory will be fully completed this year, and we will use robots to produce robots. With the support of hard and soft power, I believe that it can help the petrochemical industry in the future to create a more solid, more efficient, more reliable and smarter product supply chain!

Fill out your information, BlueSword will provide you professional service!