Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Jul 15 /2022

share to

Dr. Shen Changpeng, senior vice president of the company, recently accepted an exclusive interview with the Cold Chain Committee of China Federation of Things, focusing on the "14th Five-Year Plan for Cold Chain Logistics Development", analyzed the focus of cold chain logistics automation, and shared BlueSword's multi-industry, multi-temperature area , Multi-process intelligent cold storage solution.

As a national plan related to people's livelihood, cold chain logistics has ushered in the top-level design of industry development during the "14th Five-Year Plan" period. The "14th Five-Year Plan for Cold Chain Logistics Development" (hereinafter referred to as the "Plan") closely focuses on the cold chain logistics system, cold chain logistics at origin, cold chain transportation, cold chain logistics at sales, cold chain logistics services, and cold chain logistics innovation , cold chain logistics support and cold chain logistics supervision system, etc., put forward higher development requirements for the whole process, whole link and whole scene of cold chain logistics.

The sudden outbreak of COVID-19 has brought cold chain into the public eye, allowing the whole society to re-examine cold chain logistics from the perspective of "biosecurity". From the Huanan Seafood Market in Wuhan to the frozen food processing market in Beijing Xinfadi and Dalian, the food safety and vaccine safety issues caused by cold chain logistics have attracted more and more public attention. And with the upgrade of consumption, strengthening the supervision of cold chain circulation and improving the traceability of the whole chain will become a major issue for cold chain logistics to be solved during the "14th Five-Year Plan" period.

Cold chain logistics undertakes the mission of improving the quality of life of 1.4 billion people. At a time when land resources are increasingly scarce, labor costs are gradually rising, and user needs are becoming differentiated, establishing and improving a modern technology system for cold chain logistics has become an enterprise that improves cold chain logistics. Effective means of economic benefits can help enterprises achieve resource integration, improve operational efficiency, expand operating scale, and solve problems such as shortage of infrastructure resources such as cold storage and low level of informatization.

"Automation technology" is accurate and symptomatic, and cold storage operation is "anxious"

Under the support of multiple factors such as national policies and consumer demand, my country's cold chain logistics industry has developed rapidly, and core infrastructure resources, including cold storage, are favored by enterprises. Cold storage is an important core of the new infrastructure of cold chain logistics. According to the data from the Cold Chain Committee of China Federation of Things, the total capacity of cold storage in my country has exceeded 70 million tons in recent years, and the proportion of automated high-level three-dimensional storage is constantly rising. It can be seen from this: the future The automated high-standard warehouse will become the outlet for the new infrastructure of cold chain logistics.

In the early days of my country, the building structure of cold storage was mostly flat, the floor height was low, and the technology was relatively backward, mainly manual operation, such as artificial ground storage, etc. High-position forklifts were not used much, and stackers and AGVs were rarely used. Such as automation equipment, the technical environment is not ideal. In the past two years, with the rapid development of my country's cold chain warehousing industry, the standard requirements of cold storage users for cold chain equipment technology are also constantly improving, which also impels logistics enterprises to improve the automation level of cold storage to meet market demand.

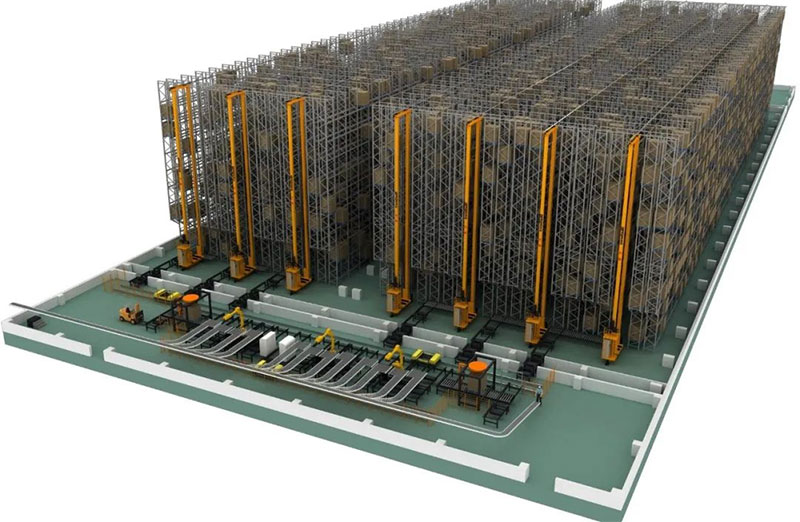

At present, traditional flat warehouses or building warehouses account for less than half of the new parks, and high-level automated stereoscopic warehouses have become the mainstream choice for users due to their excellent performance. This is mainly due to its improved space utilization and the expansion of the height of the warehouse to 25 meters or even 30 meters, which also makes some advanced technical equipment more easily accepted in the market.

One of the ultimate goals of automatic operation is to realize unmanned operation. Regardless of the cost of cold storage construction period or long-term operation cost, the investment of high-level storage is lower than that of flat storage or building storage. In the concept of the whole life cycle, the technical advantages are more obvious. Practice has proved that both large-scale leading enterprises and cost-oriented SMEs are more inclined to put automation into use after comprehensively calculating future operating costs, land costs, labor costs and other costs. Automation technology and equipment are very popular in the market, not only because of their cost advantages, but also because of the following three objective reasons:

One is

During the "14th Five-Year Plan" period, driven by favorable factors such as policy support and people's livelihood needs, the cold chain logistics market has been rapidly cultivated, which has driven the maturity and stability of equipment technology and reduced costs. Technological progress has also improved users' understanding of cold chain logistics. Recognition of the technical environment, thus realizing a virtuous circle of technology application and market cultivation.

two is

After years of economic development, land resources have gradually become scarce, and the volume of flat storage is far from meeting the total demand for storage of goods. The capacity can only be expanded in the air through automated shelves or high-level shelves, which also stimulates the development of cutting-edge technologies and promotes enterprises. Build the corresponding technical system in the library.

Dr. Shen Changpeng, senior vice president of BlueSword Technology Co., Ltd., said that ordinary stackers under 24 meters can no longer fully cover the market demand, and the height of product matching will continue to rise in the future. The super future factory under construction by BlueSword has developed a stacker crane with a height of nearly 45 meters, which is about to be put into production operation. Its operating height is second to none among similar products in the world.

The third is

In the past 3-5 years, labor difficulties have become a serious challenge faced by all walks of life. After the epidemic, on the one hand, the demand for cold storage surged, and manpower could not return to the post, making it extremely difficult to recruit workers; on the other hand, the implementation requirements for non-contact logistics operations also blocked manual participation.

In the future, with the acceleration of the "three-level node" construction process in the "Planning", large-scale state-owned enterprises, government enterprises, and private enterprises will deploy large-scale cold storage, but the speed of personnel recruitment and training is far from matching, and automation technology will become cold storage. The glue between the contradictions between market demand and talent gap. Whether it is filling the artificial gap or safeguarding logistics safety and food safety, unmanned technology must be the first.

In general, the promotion of automated high-level three-dimensional warehouses for cold storage benefits from multiple factors such as the demand for cold chain logistics, non-contact standard requirements, labor shortages, scarcity of land resources, and the advancement of technology itself. The promotion and application of automated three-dimensional warehouses will also create conditions for the adjustment of the industrial structure of cold storage and the optimization of the layout of cold chain logistics facilities.

Physical fitness: the leap from "more" to "full"

The construction of the modern technology system of cold chain logistics has already taken shape. Taking BlueSword as an example, after years of accumulation, BlueSword's product field involves the "6+1" key categories including fresh fruits and vegetables, aquatic products, meat, etc. 18°C constant temperature zone, 0 to -2°C/-2 to -8°C refrigeration zone, -18°C or -25°C freezer zone for multi-temperature zones.

Cold storage warehousing is the heart of cold chain logistics. With the increase of customers' demand for automation and customized technical solutions, BlueSword Intelligent can not only meet customers' warehousing needs, but also include dismantling and picking and automated delivery systems. As a R&D and manufacturer of a full range of intelligent logistics robots, BlueSword not only provides shelves, stackers, multi-storey shuttles, AGVs, conveyor lines, depalletizers and other items, but also customizes according to customers' differentiation It is required to provide combined logistics equipment and design the optimal systematic solution.

In the field of meat products, BlueSword has carried out in-depth cooperation with Muyuan Foods Co., Ltd. in multiple smart warehouses. Muyuan Food Co., Ltd. has always adhered to the beautiful vision of "letting people eat pork with confidence", and is committed to creating high-quality pork that is safe, delicious, healthy and environmentally friendly, and has now become a leader in the professional field. Muyuan adopts a production model of "full self-raising, full chain, and intelligence", allowing technology to empower the pig industry.

BlueSword helped Muyuan create a multi-link warehousing solution.

First of all, for the cold storage from -18 to -25 ℃, 7 double-extension stacker design is adopted, with a total of about 24,000 cargo spaces, which meets the requirements of high cleanliness food grade, and also takes into account waterproof, oil-proof and waterproof. Corrosion and meet the requirements of flushing operation on the project site. In terms of technological innovation, a robotic arm is used to replace manual coding and disassembly operations, and it is connected in series with multiple systems to achieve 24-hour uninterrupted operation. As of the third quarter of 2021, BlueSword and Muyuan Co., Ltd. have carried out multi-city project cooperation, and built several smart cold storages involving refrigeration, freezing and other temperature zones.

In terms of fruits and vegetables, BlueSword has undertaken the automation system of Baiguoyuan (Wuhan) 5.0 logistics distribution center, a leading domestic fresh food e-commerce enterprise, using the BlueSword honeycomb system, which has changed the traditional person-to-goods picking mode and completed the delivery of goods to people. The successful transformation of the picking mode has created the application of the domestic multi-wear system in the field of fresh food e-commerce.

BlueSword has independently developed the fourth-generation IoT shuttle vehicle dynamic cargo location walking positioning technology, which can accurately find the exact position of each material box. This function cooperates with the dynamic cargo location management technology of the WMS system to accurately query the location of each commodity. The batch and location can accurately realize the first-in, first-out of goods, and achieve the purpose of reducing costs and increasing efficiency through the method of finding people to select goods. The scheduling system can support two methods of picking fruit picking and sowing picking, and choose the optimal method to fulfill the order according to the order structure. The system can perform shape detection before storage, which maximizes the safety of goods and the smooth operation of equipment. The exception handling path is a roundabout design, which does not require secondary input, which is simple and efficient. Three-dimensional conveyor line design, the upper layer is put into storage, and the lower layer is empty for replenishment/return to storage, saving operating space and construction costs. The entire project achieves high efficiency of inbound and outbound picking while realizing intensive warehousing.

It is worth noting that the automation system of Baiguoyuan (Wuhan) was completed in 2020 when the new crown epidemic broke out. BlueSword overcame various difficulties in Wuhan to achieve the smooth delivery of the project, and was able to meet the delivery needs of many Baiguoyuan stores across the country at the same time. It provides a solid foundation to ensure the supply and distribution of civilian materials during the epidemic.

In the field of pharmaceutical circulation, the cold storage project co-operated by BlueSword and Sinopharm Group Shanxi Logistics Center is the first multi-pass "goods-to-person" cold storage project in the pharmaceutical industry. The air curtain divides the warehouse and the picking table into two spaces, which are transported by double-layer conveyor lines. Operators perform manual operations in a normal temperature environment, and the entire operation process does not require staff to enter the cold storage, which greatly reduces the damage to the human body caused by the low-temperature working environment. At the same time, the cold storage does not need to be opened unless there are special circumstances, which creates a more stable low-temperature environment for medicines. This project can increase the storage capacity of cold storage while improving the work efficiency and accuracy of cold chain operations. Therefore, the 3D "goods-to-person" picking method adopted by the project was subsequently copied to other logistics centers of Sinopharm Group, as well as Nanjing Pharmaceutical, Tianjin It is used in the warehousing projects of pharmaceutical distribution and pharmaceutical manufacturing enterprises such as Tianyao.

In addition, BlueSword has successfully applied the overall logistics equipment technology in many fields such as aquatic products, dairy products, and quick-frozen products. The projects of these benchmarking enterprises and leading enterprises have also verified the reliability of BlueSword's technology and products.

The demand for multiple temperature zones, multiple industries, multiple products and multiple processes is only a part of the modern technology system of cold chain logistics. BlueSword will adapt to the development of the times in the future, and strive to achieve all temperature zones, all industries, all products, all technically. Process coverage to meet complex and diverse customer needs.

At present, the new demand of some products for the temperature zone has been extended to the quick-freezing environment of -35 to -40 ℃. The operation process design of storage, sorting and transportation in this ultra-low temperature freezing zone has become a new topic that BlueSword is focusing on. To allow the product to operate normally under the condition of ultra-low temperature pressure, to ensure the stable performance of the product when the goods shuttle back and forth between different temperature zones, and to avoid the problem of frost, it is necessary to combine the overall solution, the characteristics of the stand-alone equipment and the specific environment for repeated testing. At present, BlueSword has successfully overcome the technical difficulties of components in the ultra-low temperature environment, and will launch an overall automation solution in the ultra-low temperature environment in the near future.

The iterative upgrade of customer needs has promoted the continuous improvement of the technical level of the cold chain warehousing industry, and has also helped intelligent warehousing equipment companies including BlueSword to gradually complete the puzzle of unmanned, intensive and automated operations in all temperature zones.

In the future, in terms of technical equipment, BlueSword will transition from multi-product to full-category. The definition of "full" is not only to expand new products, but to help customers improve on the basis of existing stock assets as much as possible, such as some warehouses built in the early stage. Due to the limitation of floor height or other reasons, it cannot be transformed into an automated warehouse. BlueSword will provide solutions to replace traditional forklifts, high-level forklifts and even high-level double reach forklifts with unmanned forklifts and smart forklifts to realize unmanned operations in old warehouses. Solve the problem of cold storage operation.

In terms of operation process, BlueSword will transition from "multi-process" to "full-process", from the complete automation of warehousing, picking, delivery and other links in the warehouse that has been achieved so far, to the unmanned and Intelligent development, and finally realize the unmanned operation of the whole process of cold chain storage.

future tech code

The continuous upward growth trend of the cold chain logistics market has led many cross-industry leading companies such as Vanke, Baoneng and other real estate companies to deploy the cold chain warehousing industry. These enterprises are different from the traditional business models of land enclosure and renting warehouses. Most of them are third-party cold storage operators. Based on their strong financial strength, they are more inclined to high-investment cold storage construction. Large-scale investment in civil engineering, automation equipment and other large-scale investment has also stimulated the development of the industry. .

The customers faced by such third-party companies are usually divided into two categories: those with clear needs and those with no long-term planning. For the first type of customers, BlueSword will design customized solutions based on their business type, while for the second type of customers, we need to formulate solutions with higher versatility. No matter which type of customers, we need to consider the plan for later business upgrades scalability and flexibility.

For example, customers who focus on traditional warehousing may focus on picking in the future. BlueSword's equipment and storage space solutions need to be oriented to picking parts or other personalized needs to adapt to the flexibility and flexibility of future changes.

Shen Changpeng concluded that the trend of future technology development is mainly concentrated in three aspects:

One is densification. When the land reserved for logistics construction by agricultural land and urban planning is very limited, warehouse construction will tend to be more intensive storage. From flat warehouses or building warehouses to automatic stereoscopic warehouses and ultra-high stereoscopic warehouses, the height can reach 30 meters, 35 meters or even 45 meters to contribute to a higher input-output ratio.

The second is unmanned, the technology is becoming more and more mature, and the large-scale and batch application will also highlight the economies of scale and gradually reduce the cost of equipment. However, labor costs will continue to rise with the improvement of consumption levels, and the pressure of the working environment, potential occupational disease risks, and the cost of training talents will become the shortcomings of labor operations. Unmanned operation can resolve these risks, the application scenario is not affected by the environment, the error rate is low, and the operation efficiency is high, which maximizes the reliability of product timeliness and quality.

The third is the trend of fragmentation. At present, third-party logistics mainly leases whole warehouses. In the future, it will develop into a storage form with pallets as a unit to accommodate smaller needs. Then, by expanding the scale and combining informatization and digital platforms, it will gather sand into a tower. economies of scale. For customers, these fragmented needs can only be achieved by self-built or leased whole warehouses. After the trend of using pallets as the smallest storage unit, they can also get the same high-quality services. Fragmentation demands rely more heavily on automation, and achieve economies of scale in the form of dense storage, which not only puts forward higher requirements for intelligent equipment, but also requires the construction of an intelligent platform to help small and micro owners enjoy the dividends of large-scale operations. Such as additional income or value-added services. However, how to concentrate fragmented demand and how to achieve large-scale construction and operation still needs to be explored.

The "14th Five-Year" Cold Chain Logistics Development Plan provides all-round guidance for the development of cold chain logistics in the future. In terms of cold chain warehousing, it is suggested that auxiliary policies such as the logistics park rating system can be used to guide and further promote the development of cold chain logistics. Cold storage and industry intelligent process.

Fill out your information, BlueSword will provide you professional service!