Your privacy is very important for us. When you visit our website, please agree to the use of all cookies. For more information about the processing of personal data, please go to Privacy Policy.

Sep 21 /2022

share to

The logistics attributes of the home industry itself are diverse, coupled with a variety of special challenges such as high shelves, paper pallets, thin pallets, variable size jacks, etc., making the warehouse automation upgrade of a global famous home brand encounter a lot of difficulties. After considering the industry characteristics, warehouse environment, special pallets, product specifications and other practical situations, BlueSword Intelligent successfully built the first warehouse for the brand that can automate the handling of its unique paper pallets and high shelf access.

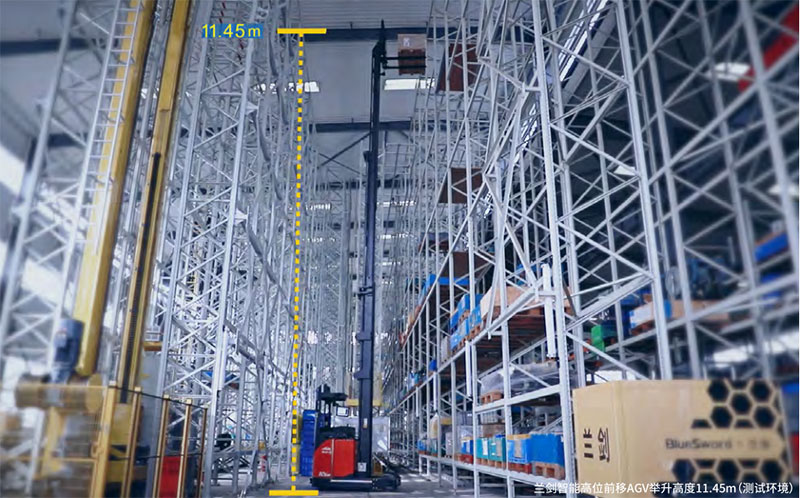

BlueSword intelligent high forward moving AGV lifting height 11.45m (test environment)

With the rapid development of the national economy, the consumption habits of the people are also changing. Especially the new generation of consumer subjects pursue new, fast, personalized and differentiated consumption experience, which makes the new home retailing develop rapidly, but at the same time the problems and pain points of home logistics are becoming more and more prominent, which puts forward higher requirements on the automation level of logistics equipment.

Industry background

Unlike other industries, the home furnishing industry itself has special and diverse logistics attributes. For example, there are many kinds of logistics objects, a wide range, non-standardized, and oversized, overweight, irregular and easy to break; logistics operations are intensive, low operational efficiency, high error rate and safety hazards; warehousing covers a large area, low storage ping efficiency, etc.

Along with the new retail trend of omni-channel marketing, a variety of procurement and order patterns also lead to increased difficulty in order processing and distribution, coupled with the increasing cost of land and labor costs, home logistics urgently needs to apply intelligent technology to achieve supply chain upgrades. In the whole home supply chain system, warehousing logistics is an important link that needs to be solved urgently.

Project Overview

This project is jointly built by BlueSword and a global famous home furnishing brand, and is located in the CP warehouse of the brand in South China. Since its official opening, this CP warehouse has been providing a large number of furniture and household goods distribution services for the global shopping mall stores of this home furnishing brand in South China and Southeast Asia every day. Before the implementation of this project, the cargo handling process of this CP warehouse in South China was still carried out manually or manually driven by forklift, especially the high shelf access process was not automated, and there was a common problem of low efficiency in the industry.

In order to help upgrade the global supply chain strategy, the team of South China CP warehouse of the home furnishing brand started to research and plan for innovative solutions, aiming to realize the complete unmanned end-product warehouse. The start of the South China CP warehouse high forward AGV automation project is the first step to put into practice the "unmanned warehouse for end products". The project requires AGVs to be able to realize a variety of complex operating scenarios in a variety of different working environments, and there are certain technical difficulties.

Project technical difficulties

1. Speciality of the pallet

The pallet in this project is made of special paper material, which is highly fragile and requires the AGV to control the position of the jack and the depth of the pallet during the handling operation. And the height of the paper pallet is low, only 45mm, compared with the conventional 110mm pallet height, its requirements for the accuracy of the fork are higher.

2. Wide variety of pallets

The pallets in this project have inconsistent jacks and many specifications, and the AGV forks need to intelligently identify the pallets and jacks, and intelligently adjust the pitch for different jack pallets to ensure stability. At the same time, it needs to identify the labels of goods on different sizes, and adjust the depth of fork reach according to the size of the obtained goods, in order to prevent the fork from reaching too far and touching the goods.

3. Ground stack cargo placement scene is rich

There are rich application scenarios such as multi-layer up and down stacking and different size pallets up and down stacking, which are different from the common ones of finding and picking up goods according to the cargo location, AGV needs to realize automatic cargo finding according to the area.

4.High-level racking and wooden square pad beam

The CP warehouse shelves belong to the high level shelves, need to ensure the safety of the premise to achieve a high level of accurate pick and place the goods, to prevent damage to the goods caused by dragging. In addition to the normal flat plate, there is also a platform for placing wooden cushion beams on the shelf platform. It is necessary to precisely match the pallet with the wooden cushion beams to ensure the stability and safety of goods storage.

Project technology innovation

Under the premise of comprehensive consideration of industry characteristics, warehouse environment, special pallets, product specifications and other practical situations, and in response to various special problems in the project, such as high level shelves, paper pallets, thin pallets, variable size jacks, etc., as the key technology provider and core equipment supplier, BlueSword Intelligent provided a set of customized and flexible solutions, and through extensive research and development, repeated testing and continuous correction, successfully developed The product mainly has the following technical innovation highlights.

BlueSword intelligent high forward AGV effect

1. Automatic pallet correction detection

In view of the technical difficulties such as the thin height of pallet holes in the project, BlueSword intelligent high forward moving AGV based on 3D vision detection system and related technology algorithm, can accurately detect and identify the 3D space position of the pallet when picking up goods, and timely adjust the position of the vehicle and forks through the software system, realizing automatic pallet correction detection and accurate pickup. At the same time, it can also realize pallet abnormal alarm, detecting pallet status when picking up, and if there is pallet deformation, pallet tilt serious and other pallet abnormalities, the vehicle will stop and alarm immediately.

2. Precise navigation, multi-layer stacking

The high forward AGV in this project adopts the advanced laser SLAM navigation-based composite navigation method, which does not require too much transformation of the environment, short implementation cycle for map building and online real-time map updating, and can cope with the complex dynamic environment changes in this CP warehouse, and the positioning accuracy can reach ±5mm.

In the ground stack handling area of the project, in response to the customer's need to achieve multi-layer stacking pick and place goods, BlueSword Intelligent High Forward AGV can use 3D vision system to detect the number of layers of goods in the ground stacking area in real time and achieve multi-layer stacking pick and place goods. It can also detect and find the position of goods in the ground stacking area in real time, and find the goods from "point" to "surface", and at the same time, it can realize self-planning of empty space and identify the empty channel to put the goods.

3. High-level accurate picking and placing of goods

The high level forward moving AGV in this project can lift up to 11.45 meters, with a maximum load of 2 tons, and can complete the task of lifting goods in and out of the warehouse, integrating walking, steering, fork lifting, gantry forward moving, recycling, fork side moving and forward and backward tilting functions, without civil construction or environmental transformation, and can realize "plug and play". "unmanned transformation and upgrade.

4. Safety and efficiency

The high forward moving AGV in this project has 360° 2D laser obstacle avoidance coverage, high oblique downward laser 3D obstacle avoidance, fork anti-collision detection, gantry shaking amount detection, anti-dragging pallet detection, voice sound and light alarm, safety touch edge, emergency stop button and many other safety protection measures. The Bessel curve-based AGV vehicle control algorithm is also able to achieve a significant increase in operating efficiency.

With the above technical innovations, BlueSword has helped the South China CP warehouse of this global famous home furnishing brand to realize handling automation and high level access automation, completing the goal of warehouse automation upgrade. After nearly 10,000 tests, the project has been successfully accepted in 2021.

BlueSword intelligent high forward AGV shelf picking and placing goods (actual operation scene at customer site)

Project implementation effect

1. Improve operational efficiency and economic benefits

The successful implementation of this project has greatly improved the automation level of handling and storage in this CP warehouse, and the efficiency of warehousing and handling has been greatly improved, laying the foundation for ensuring its global long-term high supply chain efficiency and low logistics cost, and improving the level of sustainable development. Fully automated handling replaces manually operated forklifts, and also significantly reduces manual labor and labor costs. As a result of the improved handling efficiency, distribution time is reduced, thus enhancing consumer reputation of the brand and creating long-term economic benefits for the company.

2. Improve safety management

Home industry large, heavyweight goods such as the use of manual handling, high risk factor. The application of high forward AGV avoids the risk of manual operation of forklifts, reduces the risk factor and maximizes the protection of human safety. The application of automated handling equipment reduces errors in the process of goods handling and information processing, also greatly ensures the safety of goods pick and place, and overall improves the management level of the warehouse.

BlueSword intelligent high forward moving AGV multi-layer stacking pick and place goods (actual operation scene at customer site)

3. High promotion value

For the industry, the implementation of this project helps to improve the level of warehouse automation in the whole industry, and has a high industry innovation and extensive promotion value in promoting the automation upgrade of the national home furnishing supply chain, and has won the "2021 National Home Furnishing Logistics Excellent Case" award. For the famous home furnishing brand, this CP warehouse project is its first warehouse that can automate handling and high level shelf access for its own paper pallet goods, and it has an important strategic pilot significance to enhance the overall automation of its global CP and DC in the future.

Home industry supply chain of digital intelligence upgrade, can not be separated from the intelligent logistics technology support. In the face of new trends and challenges in the home furnishing industry, in addition to the above-mentioned high forward AGV automation solutions, BlueSword Intelligence also proposes innovative solutions covering multiple scenarios of customization and flexibility at the factory and store ends. For example, the automated storage solution of the factory end of the plate warehouse and finished goods warehouse can make the storage objects of oversize, overweight and overwidth more stable, safer and high-speed access and handling; while in the logistics center of the store end, in view of the diversified logistics attributes of the home furnishing industry, an integrated storage solution is proposed to realize the automated access of all sizes of goods in the same warehouse.

As one of the few superior enterprises in the field of intelligent logistics system with the capability of self-research and self-production of hardware and software, BlueSword will continue to carry out technological innovation and service upgrade in the future, and continue to provide customers with higher-end intelligent logistics robots and innovative industry solutions based on the strength of hardware and software and the core advantage of customization and flexibility for the development changes in the home furnishing industry, so as to create value for enterprises continuously.

Fill out your information, BlueSword will provide you professional service!